Efficiency Through Design: How Thin Wall Plastic Mould Reduces Material Use

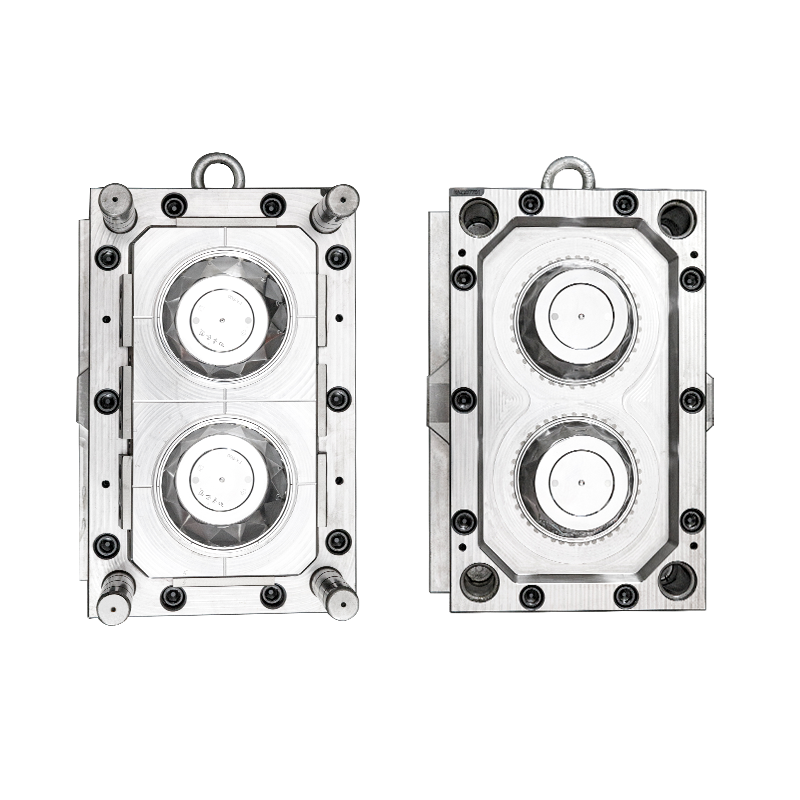

Thin wall plastic mould technology has emerged as a sophisticated manufacturing solution that enables production of lightweight components without compromising structural integrity or functionality. This specialized moulding approach focuses on creating plastic parts with significantly reduced wall sections, typically ranging from 0.5 to 1.0 millimeters, through advanced engineering and precise process control. The implementation of thin wall plastic mould systems requires thorough understanding of polymer behavior under high-speed injection conditions and elevated pressure parameters. These manufacturing systems support the production of components that meet modern requirements for material efficiency, reduced weight, and enhanced sustainability across various application sectors.

The design complexity of thin wall plastic mould systems necessitates comprehensive analysis and careful planning to ensure manufacturing success. Flow simulation software plays a crucial role in thin wall plastic mould development, predicting material behavior during the extremely rapid filling process. Venting design in thin wall plastic mould configurations requires particular attention to prevent air trapping that could cause filling imperfections. Ejection system planning for thin wall plastic mould applications must account for reduced structural support while ensuring damage-free part removal. These design aspects demonstrate the technical sophistication involved in developing successful thin wall plastic mould systems.

Processing parameters for thin wall plastic mould operations differ significantly from conventional injection moulding requirements, demanding specialized equipment capabilities. Injection speed requirements for thin wall plastic mould applications typically exceed those of standard moulding processes to ensure complete cavity filling before material solidification. Pressure parameters in thin wall plastic mould operations must maintain adequate levels to overcome flow resistance through narrow cavities. Temperature control in thin wall plastic mould processes requires precise management to facilitate rapid cycling while preventing material degradation. These processing conditions highlight the technical challenges associated with thin wall plastic mould manufacturing.

Material development has played a significant role in advancing thin wall plastic mould capabilities, with polymer manufacturers creating specialized compounds for these applications. High-flow materials with low viscosity characteristics enable successful thin wall plastic mould operations by reducing flow resistance during injection. Enhanced thermal stability in materials developed for thin wall plastic mould applications prevents degradation during high-temperature processing. Mechanical property retention in materials designed for thin wall plastic mould use ensures finished products meet performance requirements despite reduced wall sections. These material advancements continue to expand the possibilities for thin wall plastic mould applications.

Thin wall plastic mould technology represents a advanced manufacturing methodology that addresses contemporary needs for efficient material usage and lightweight design. The technical challenges associated with these mould systems have driven innovations in design, materials, and processing techniques that benefit broader manufacturing practices. The continued evolution of thin wall plastic mould capabilities supports production of sophisticated components that meet demanding application requirements while promoting manufacturing sustainability. This specialized field exemplifies how manufacturing technology continues to progress, enabling creation of advanced products that balance performance, economy, and environmental considerations.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness