Digital Textile Printing in Delhi: Revolutionizing the Fabric Industry

Delhi, India’s bustling capital city, is a melting pot of culture, commerce, and creativity. Known for its thriving garment markets, fashion hubs, and home furnishing businesses, Delhi is also witnessing a rapid transformation in textile production. One of the biggest game-changers has been the rise of digital textile printing in Delhi.

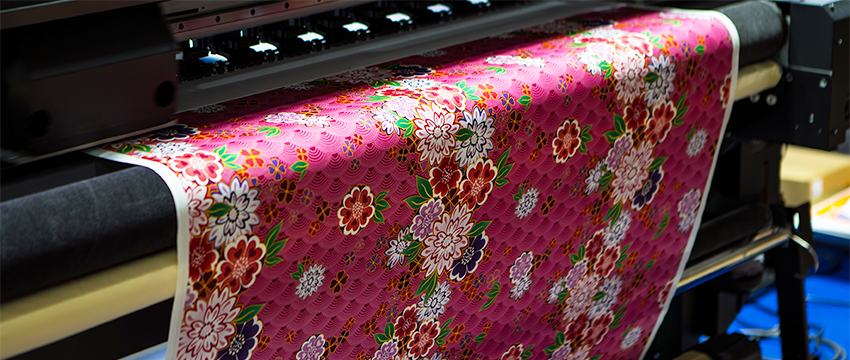

Digital textile printing has redefined how fabrics are designed, customized, and produced. Unlike traditional block or screen printing, which require labor-intensive setups, digital printing directly transfers digital designs onto fabrics using advanced inkjet technology. The result? Faster production, detailed designs, eco-friendly methods, and greater flexibility for both small and large-scale printing needs.

In this article, we’ll explore how digital textile printing is shaping Delhi’s fabric industry, its process, applications, advantages, challenges, and what the future holds.

What is Digital Textile Printing?

Digital textile printing is a modern technique where digital designs are printed directly onto fabric using specialized printers. Instead of relying on stencils or screens, this method uses inkjet technology and textile-specific inks to produce vibrant, detailed, and durable prints.

Key Features of Digital Textile Printing:

-

High-definition prints with sharp details.

-

Ability to handle multiple colors and gradients.

-

Reduced water and chemical consumption.

-

Quick turnaround time compared to traditional methods.

-

Flexibility to print small batches or large orders.

Why Delhi is Emerging as a Hub for Digital Textile Printing

Delhi has always been a significant player in India’s textile ecosystem. Its bustling fabric markets like Chandni Chowk, Lajpat Nagar, and Nehru Place, along with NCR’s industrial hubs in Noida, Gurgaon, and Faridabad, make it a hotspot for textile trade and manufacturing.

Several factors explain the growing adoption of digital textile printing in Delhi:

-

Fashion Boom – Delhi’s fashion designers, boutiques, and fashion schools demand high-quality custom prints for their collections.

-

E-commerce Growth – Online brands prefer digital printing for quick, customized apparel and accessories.

-

Export Opportunities – Delhi NCR-based exporters rely on digital printing to meet global quality standards.

-

Event Merchandise – From customized T-shirts to promotional banners, event organizers use digital printing extensively.

-

Interior Décor Market – Home furnishing businesses demand printed fabrics for curtains, upholstery, and décor items.

Advantages of Digital Textile Printing

Superior Print Quality

Digital printing produces high-resolution designs with precise details and vibrant colors, ideal for complex fashion patterns.

Cost-Effective for Small Runs

Unlike screen printing, which has high setup costs, digital printing is economical for small batches and even single-piece customization.

Eco-Friendly Production

Digital printing uses less water, fewer chemicals, and minimizes fabric wastage, supporting sustainable practices.

Faster Turnaround

Design-to-print speed is significantly higher, which is essential for fast fashion and event-based requirements.

Design Flexibility

From traditional motifs to contemporary abstract art, digital printing can bring any creative design to life.

Applications of Digital Textile Printing in Delhi

The versatility of digital printing makes it useful across various industries:

-

Fashion & Apparel: Sarees, lehengas, kurtas, shirts, dresses, and activewear.

-

Home Furnishings: Bedsheets, cushion covers, curtains, and sofa fabrics.

-

Sportswear & Uniforms: Jerseys, yoga wear, and personalized team uniforms.

-

Promotional Merchandise: Event banners, corporate T-shirts, and customized giveaways.

-

Accessories & Décor: Bags, scarves, wall fabrics, and interior upholstery.

The Process of Digital Textile Printing

Digital textile printing is efficient yet precise. Here’s how it works:

-

Design Creation – Designers prepare digital patterns using software like Adobe Illustrator or Photoshop.

-

Fabric Pre-Treatment – Fabrics are treated with special solutions to ensure proper ink absorption.

-

Printing – Digital inkjet printers directly apply the design onto the fabric.

-

Fixation – Heat or steam is applied to fix the ink permanently into the fibers.

-

Finishing & Quality Check – The fabric undergoes washing, drying, and inspection before delivery.

Challenges of Digital Textile Printing in Delhi

Despite its popularity, there are challenges:

-

High Equipment Costs – Industrial digital printers and inks are expensive for small businesses.

-

Fabric Compatibility – Some fabrics may not absorb inks properly without special treatment.

-

Need for Skilled Workforce – Technicians and designers are essential for maintaining print quality.

-

Market Competition – With many service providers, quality and innovation are key differentiators.

The Future of Digital Textile Printing in Delhi

The future is bright as both demand and technology evolve.

Key Trends to Watch:

-

Eco-Friendly Inks – Use of water-based, biodegradable inks is growing.

-

Automation & AI – Smarter printers will increase efficiency and reduce errors.

-

Mass Customization – Rising demand for personalized apparel and décor items.

-

Global Exports – Delhi’s exporters will increasingly leverage digital printing to meet international trends.

Choosing the Right Digital Textile Printing Service in Delhi

With so many service providers, it’s essential to choose wisely.

Key factors to consider:

-

Experience & Reputation – Established service providers deliver better results.

-

Technology Used – Look for modern machines capable of reactive, sublimation, or pigment printing.

-

Fabric Options – Ensure compatibility with your chosen fabric type.

-

Pricing & Turnaround – Balance affordability with quality.

-

Customer Support – Responsive after-sales service is important for reorders.

FAQs

Which fabrics are suitable for digital textile printing?

Digital printing works well on cotton, silk, polyester, nylon, and blends, though ink type must match fabric composition.

Is digital textile printing eco-friendly?

Yes. Compared to traditional methods, it uses less water, generates less waste, and consumes fewer chemicals.

Can I order small quantities with digital printing?

Absolutely. Digital printing is ideal for small batches or even single-piece customization.

How durable are digitally printed fabrics?

With proper fixation and finishing, the prints are long-lasting, colorfast, and resistant to fading.

How much does digital textile printing cost in Delhi?

Costs vary based on fabric, design complexity, and quantity. Generally, it is more cost-effective for small and medium runs.

Conclusion

Digital textile printing in Delhi is revolutionizing the way fabrics are designed, produced, and marketed. By offering high-quality, eco-friendly, and customizable prints, it has become a preferred choice for fashion designers, exporters, event organizers, and home furnishing businesses.

As Delhi continues to strengthen its position as a textile and fashion hub, digital printing will play a vital role in meeting modern demands for speed, sustainability, and personalization. For anyone looking to innovate in fashion, décor, or promotional products, digital textile printing in Delhi is not just a service—it is the key to turning creativity into reality.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness