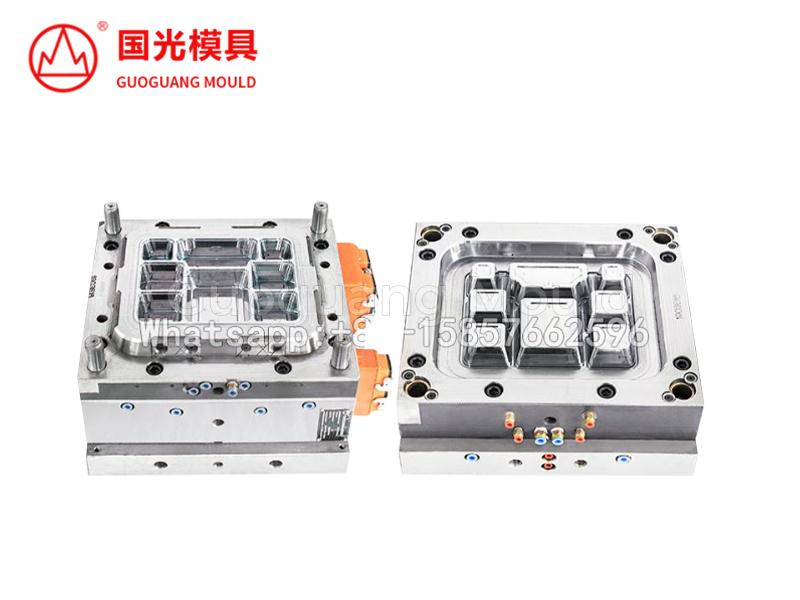

Professional Microwave Container Mould Manufacture Standards

Professional microwave container mould manufacture has evolved to meet increasing demands for convenient, safe food packaging compatible with microwave heating. This specialized manufacturing discipline combines precision engineering with knowledge of microwave-food interactions to create functional container systems. The design phase in professional microwave container mould manufacture focuses on creating containers that distribute microwave energy evenly while withstanding temperature variations from freezer to microwave. The expertise applied in professional microwave container mould manufacture results in containers that protect food quality during microwave preparation while maintaining structural integrity.

The engineering approach in professional microwave container mould manufacture addresses several unique technical challenges not present in conventional container mould production. Thermal management during professional microwave container mould manufacture must account for the different expansion rates of various mold components operating at elevated temperatures. The gating systems designed during professional microwave container mould manufacture require particular attention to prevent material degradation that could affect microwave transparency. Cooling channel layouts in professional microwave container mould manufacture must ensure uniform heat extraction to maintain consistent cycle times and dimensional stability. These engineering considerations make professional microwave container mould manufacture a distinct specialization within tool making.

Production methodology in professional microwave container mould manufacture utilizes advanced machining technologies to achieve the precise geometries required for microwave-safe containers. Computer-numerical-controlled milling centers employed in professional microwave container mould manufacture create complex cavity forms with tight tolerances. Electrical discharge machining in professional microwave container mould manufacture produces intricate details and sharp corners that would be challenging with conventional cutting tools. The polishing techniques applied in professional microwave container mould manufacture create surface finishes that facilitate easy container release while maintaining optical clarity for product visibility. These manufacturing capabilities support the quality standards expected from professional microwave container mould manufacture.

Testing and validation procedures in professional microwave container mould manufacture verify that finished molds produce containers meeting functional requirements for microwave use. The testing phase in professional microwave container mould manufacture includes trial runs that simulate production conditions while monitoring container performance. Microwave heating tests conducted during professional microwave container mould manufacture evaluate temperature distribution, container deformation, and food heating efficiency. Pressure resistance checks in professional microwave container mould manufacture ensure containers maintain seals under microwave heating conditions. These validation steps complete the professional microwave container mould manufacture process, ensuring delivered molds perform as intended in consumer applications.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness