How Thin Wall Plastic Mould Are Manufactured

Thin wall plastic mould technology enables efficient production of lightweight plastic packaging and components that meet specific performance requirements. These specialized tools represent significant investments in precision engineering that translate into material savings and manufacturing efficiency. The development of a new thin wall plastic mould begins with comprehensive design analysis that simulates material flow, cooling patterns, and structural integrity under high injection pressures. This design phase for a thin wall plastic mould ensures the finished tool will produce parts with consistent wall thickness and dimensional stability.

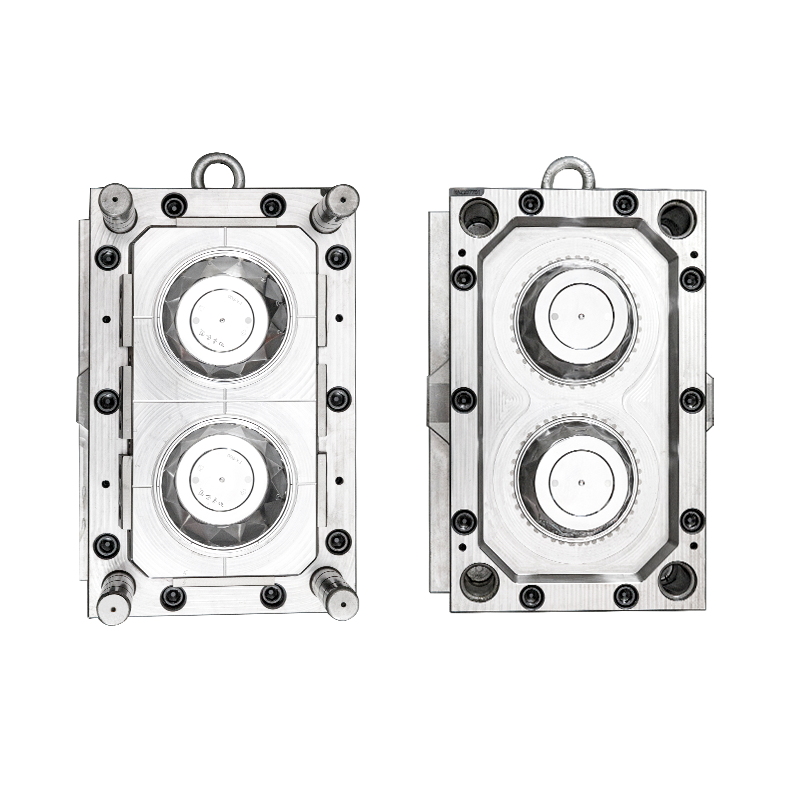

The manufacturing process for a thin wall plastic mould involves computer-controlled machining of hardened steel blocks to create precise cavity and core components. The machining accuracy for a thin wall plastic mould is particularly important for maintaining uniform wall thickness across part surfaces. The surface finishing of a thin wall plastic mould cavity affects both the appearance of finished parts and their release characteristics. Texturing or polishing operations on a thin wall plastic mould create specific surface qualities on produced items. These manufacturing steps ensure the thin wall plastic mould meets specifications for part production.

Production efficiency with a thin wall plastic mould depends on optimized cycle times that balance filling, cooling, and ejection phases. The reduced wall thickness of parts from a thin wall plastic mould allows shorter cooling times compared to thicker plastic items. The injection phase for a thin wall plastic mould requires high injection speeds and pressures to fill cavities completely before material solidification. The ejection system in a thin wall plastic mould must operate precisely to remove finished parts without distortion or damage. These process parameters for a thin wall plastic mould contribute to economical manufacturing of thin-walled plastic products.

Quality verification for parts produced with a thin wall plastic mould includes dimensional checks, wall thickness measurement, and functional testing. Parts from a thin wall plastic mould must meet structural requirements despite their reduced material usage. The consistency of a thin wall plastic mould directly influences production yield and part performance. Regular monitoring of parts from a thin wall plastic mould helps identify tool wear or maintenance needs before they affect product quality. These quality practices ensure a thin wall plastic mould continues producing acceptable parts throughout its production life.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness