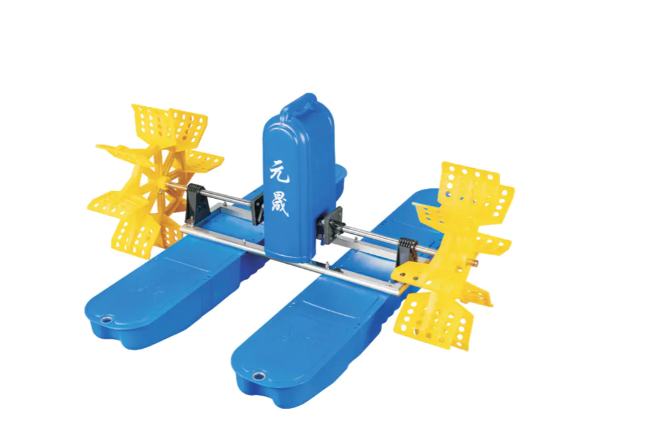

Aquaculture Machine Aerator Deployment in Recirculating Systems and Ponds

The Aquaculture Machine Aerator plays a critical role in both static pond systems and modern recirculating aquaculture systems (RAS), where maintaining consistent water quality is non-negotiable. Operators increasingly evaluate aerators not just by capacity but by oxygen-transfer rate (kg O₂ per kW·h), circulation depth, and coverage radius. In many installations, upgraded aerator models demonstrate significantly higher performance than older paddle-wheel or coarse-bubble units.

In practice, an aerator in a pond system might be required to achieve uniform mixing across depths of 1.2 metres or more, reach tens of metres of horizontal radius, and sustain dissolved-oxygen above threshold values during hot or high-stock periods. Production teams frequently ask: what motor power and float design will deliver this performance? Materials and manufacturing quality matter for buoyance stability, corrosion resistance and motor reliability.

Technological enhancements now include automated DO sensors, remote monitoring of power consumption and cloud-based logging that allows managers to compare actual versus rated aerator performance. Some units on the market introduce solar or hybrid power drive options, useful in remote or low-grid-access farms where energy cost is a concern. These advancements ensure that the aerator integrates into smarter farm management systems.

Maintenance and lifetime cost are also key factors. Factory teams must monitor seals, bearings, propellers or diffuser membranes for wear, particularly in high‐salinity or post-harvest conditions. Correct installation, calibration of floats and alignment of circulation patterns reduce dead zones and improve longevity. The aerator’s ability to remain reliable under repeated cycling and heavy loads distinguishes serious models.

Overall, the Aquaculture Machine Aerator delivers far more than basic oxygenation—it provides measurable improvements in water circulation, system monitoring and operational cost. Farms that specify and install with attention to technical detail are better positioned to extract full value from aerator deployment.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness