Sterile Wound Dressing Best Practices in Handling and Storage

When using a sterile wound dressing, correct handling, storage, and application are key considerations. Maintaining the product in its original sealed packaging until use ensures it remains functional. Environmental factors such as heat, moisture, and sunlight can affect adhesion and structural integrity, so storage in a cool, dry area is recommended.

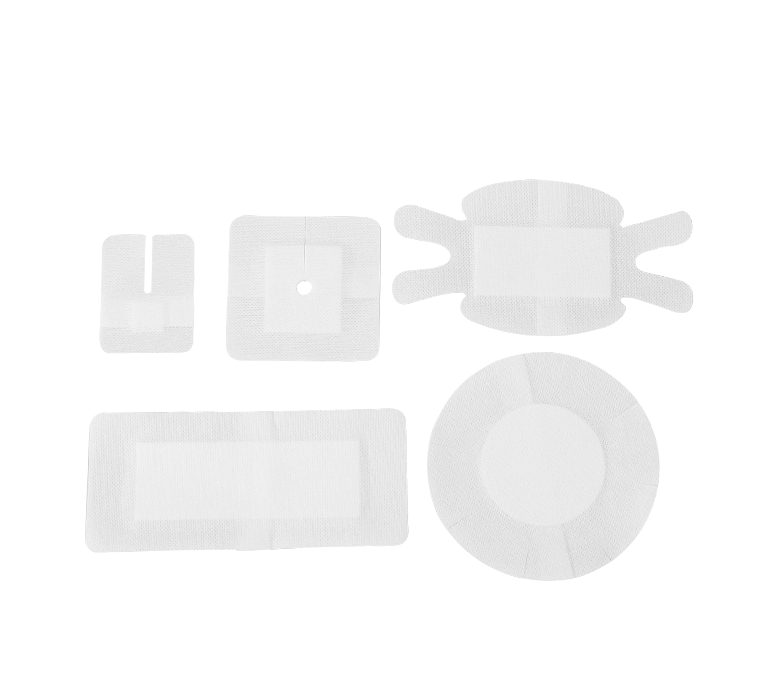

Application begins by choosing an appropriate size so that the dressing fully covers the affected area with a margin beyond the edges. The area beneath should be gently cleaned and dried to allow the dressing to adhere properly. Dressings should be secured comfortably—not too tight to cause restriction, and not loose enough to shift with movement.

Replacement frequency depends on factors such as moisture, movement, and visible wear. Observing when a dressing begins to curl or loosen helps determine when it should be replaced. Some materials retain form longer than others, and choosing the right type for daily situations supports consistent use.

Stock management also matters. Checking expiration dates, avoiding damaged packages, and rotating inventory helps preserve functionality. Users benefit from understanding how to handle the product correctly and when to replace it.

In conclusion, proper use of a sterile wound dressing requires attention to storage, handling, application, and replacement timing. Following these practical steps ensures it performs as intended and supports clean, organized care practices.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness