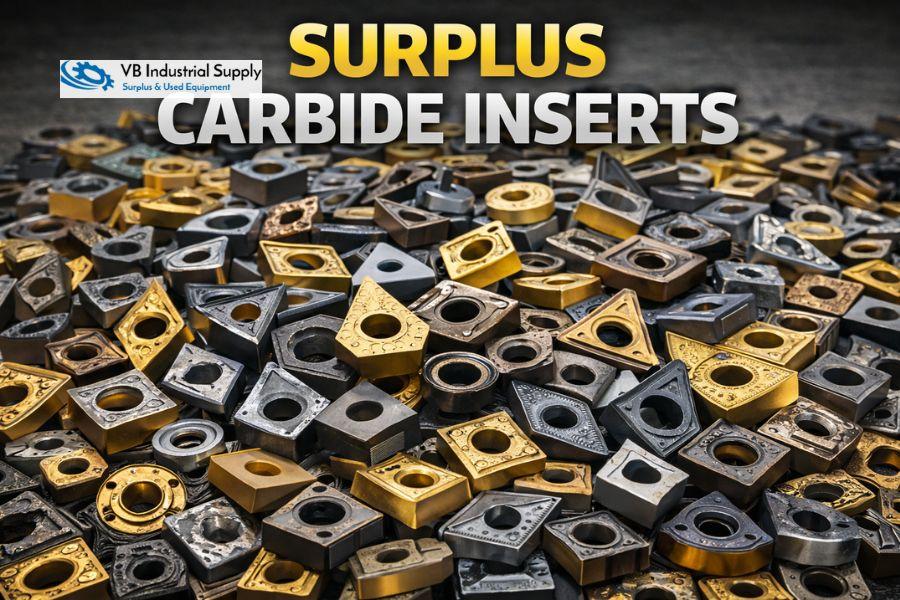

Surplus Carbide Inserts: Maximize Value, Minimize Cost in Machining Operations

In today’s competitive manufacturing and machining environment, achieving operational efficiency while controlling costs is fundamental. One often overlooked opportunity lies in surplus tooling — especially surplus carbide inserts, which remain in high demand across metalworking shops, industrial facilities, and machine shops around the world. For companies looking to optimize tooling budgets, extend equipment life, and support more sustainable processes, surplus carbide inserts offer unparalleled value.

At VB Industrial Supply, we specialize in industrial surplus equipment and tooling — including a wide assortment of carbide inserts and cutting tools. With years of experience helping machinists, maintenance teams, and procurement professionals find affordable tooling solutions or sell their surplus stock, we know how impactful surplus carbide inserts can be for your bottom line.

What Are Carbide Inserts and Why They Matter

Carbide inserts are small, replaceable cutting tool components used in metalworking operations such as turning, milling, threading, and grooving. Made from tungsten carbide, these inserts are extremely hard, wear-resistant, and capable of maintaining a sharp cutting edge under intense operating conditions.

Key Benefits of Carbide Inserts

-

Superior Cutting Performance: Carbide maintains edge sharpness longer than HSS or other materials, delivering consistent finishes even in high-speed operations.

-

Extended Tool Life: Longer life reduces frequent changeovers and tool spend.

-

Cost-Effective Machining: Although the upfront cost may be higher, carbide inserts often result in lower overall tooling expenses due to reduced wear and replacement frequency.

-

Versatility: Carbide inserts come in numerous shapes, grades, and coatings, making them suitable for a range of materials from steel to aluminum and beyond.

Given their performance and adaptability, carbide inserts are a cornerstone of modern machining — which explains why surplus carbide inserts remain highly sought after in secondary markets.

Why Buy Surplus Carbide Inserts?

Industrial surplus tooling, like surplus carbide inserts, represents a smart procurement strategy for shops and operations of all sizes. Rather than purchasing all tooling new and at full price, buyers can take advantage of surplus stock like the products offered at VB Industrial Supply.

1. Significant Cost Savings

Surplus carbide inserts are frequently new old stock (NOS) — unused tooling still in excellent condition but sold at a fraction of the price compared to buying new through standard distribution channels. These savings often range from 30–70% off list pricing, enabling companies to reinvest budget into other areas of their business.

2. Rapid Availability

Supply chain delays and long tooling lead times can halt production or delay project timelines. Surplus carbide inserts are typically available in-stock and ready to ship — meaning you can keep machines running without unnecessary waits.

3. Access to Hard-to-Find Tooling

Surplus inventory often includes rare or discontinued carbide insert sizes and grades that may no longer be available from original tooling manufacturers. For shops maintaining older machines or specialized tooling setups, this access is invaluable.

4. Sustainability and Waste Reduction

Using surplus tooling supports circular economy principles. Instead of letting high-performance parts sit unused or become waste, surplus carbide inserts are given a second life, reducing environmental impact and supporting more sustainable industrial practices.

Examples of Surplus Carbide Inserts Available

At VB Industrial Supply, our tooling inventory is diverse and constantly updated, including products such as:

-

New surplus Walter, Kennametal, and Iscar carbide inserts — suitable for turning, milling, and threading applications.

-

NOS (New Old Stock) Sumitomo and Seco carbide inserts with various geometries.

-

Bulk packages and lots of carbide insert sets for shops managing multiple machines.

Whether you’re replacing worn tooling, restocking a maintenance crib, or sourcing special grades, surplus inserts allow you to shop smart without skipping quality.

Selling Surplus Carbide Inserts — Turn Inventory Into Cash

Many machinists and companies find themselves with surplus carbide inserts due to overordering, project changes, tooling standardization, or shop cleanouts. Instead of letting valuable tooling gather dust, you can sell surplus carbide inserts to trusted buyers — and VB Industrial Supply is here to help.

Why Sell to VB Industrial Supply?

-

Fast Appraisals: We provide competitive quotes quickly.

-

Hassle-Free Process: Just send a list or photos of your surplus tooling — we handle the rest.

-

Shipping Support: We cover logistics, whether you have a few boxes or a full pallet of tooling.

-

Reliable Payment: Once verified, payment is issued swiftly — turning excess inventory into working capital.

Selling your surplus carbide inserts not only clears valuable space in your tooling crib but also recoups investment costs that can be reinvested into production upgrades, workforce training, or other operational needs.

Best Practices for Handling Surplus Carbide Inserts

To maximize return and utility from surplus carbide inserts, consider these tips:

Organize and Label Inventory

Accurate identification of inserts by part number, grade, and geometry helps both buyers and internal tooling managers track inventory efficiently. Organized tooling also typically fetches higher resale value.

Document Condition

Clearly describe whether inserts are NOS (new old stock), unused, or lightly used. This transparency speeds up evaluation and pricing.

Group Similar Types

Selling or purchasing inserts in matched lots (e.g., same size and grade) benefits both parties by simplifying transactions and improving stocking efficiency.

Leverage Trusted Buyers

Work with reputable industrial surplus buyers who understand carbide tooling and machining requirements — like VB Industrial Supply — to ensure fair offers and smooth transactions.

Conclusion

Surplus carbide inserts offer a powerful opportunity for cost-effective machining, sustainable inventory management, and improved tooling strategy. Whether you want to buy affordable inserts for your operations or sell unused inventory to unlock working capital, surplus tooling should be a vital part of your industrial planning.

At VB Industrial Supply, we provide a robust marketplace for surplus carbide inserts, along with fast quotes, dependable handling, and logistics support to make every transaction seamless. With our industry expertise and extensive inventory, we help manufacturing teams stay productive, cost-efficient, and competitive — without compromise.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness