Material Selection for Magnetic Latching Relay Parts

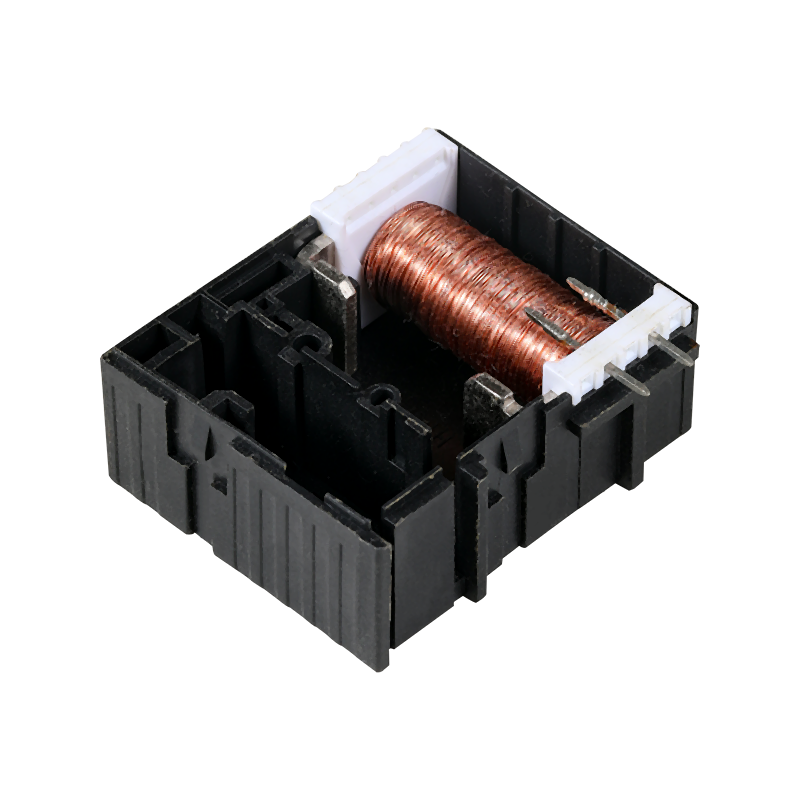

The development of effective magnetic latching relay components involves numerous engineering considerations that balance electrical requirements, mechanical performance, and magnetic characteristics. Designers must carefully select materials and configure elements to ensure reliable operation while meeting specific application requirements. The magnetic latching relay components must work in precise harmony to achieve the desired bistable operation with minimal energy consumption. This design process requires thorough understanding of magnetic principles, electrical contact behavior, and mechanical dynamics. The resulting magnetic latching relay components represent a careful integration of various engineering disciplines to create a reliable and efficient switching device.

Material selection plays a crucial role in the performance of magnetic latching relay components. The permanent magnet must maintain stable magnetic properties over time and across temperature variations, typically requiring materials like neodymium or ferrite compounds. The core and armature materials need high magnetic permeability with low coercivity to ensure responsive operation while minimizing residual magnetism. Electrical contacts require materials that provide good conductivity, resistance to welding, and durability against arcing. The housing materials must offer mechanical strength, thermal stability, and sometimes specific insulation properties. Each material choice among the magnetic latching relay components affects overall performance and reliability.

The magnetic circuit design represents a fundamental aspect of developing effective magnetic latching relay components. Engineers must calculate and optimize the flux paths to ensure sufficient holding force while allowing reliable switching with reasonable coil energy. The arrangement of magnetic latching relay components within this circuit determines the efficiency of magnetic energy utilization and the stability of both switch positions. Air gaps, magnetic shunts, and pole face configurations require precise engineering to achieve the desired magnetic characteristics. This magnetic design directly influences the performance, size, and energy requirements of the magnetic latching relay components.

Mechanical considerations significantly impact the design of magnetic latching relay components. The movement mechanism must provide smooth operation with minimal friction while maintaining precise alignment of all elements. Spring forces must be balanced against magnetic forces to ensure reliable operation without excessive energy requirements. The structural elements supporting the magnetic latching relay components must maintain dimensional stability under varying thermal conditions and mechanical stresses. These mechanical aspects require careful analysis and testing to ensure long-term reliability and consistent performance throughout the device's operational life.

The design of magnetic latching relay components involves complex engineering decisions that balance multiple competing requirements. The integration of magnetic, electrical, and mechanical elements creates a sophisticated device that provides reliable bistable switching with minimal energy consumption. The careful selection of materials and precise configuration of all magnetic latching relay components ensure optimal performance in various applications. This engineering approach results in devices that offer significant advantages in energy efficiency and reliability, making magnetic latching relay components valuable solutions for modern electrical and electronic systems where power conservation and dependable operation are important considerations.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness