The Steel Cord Conveyor Belt: A Solution for Long-Distance Transport

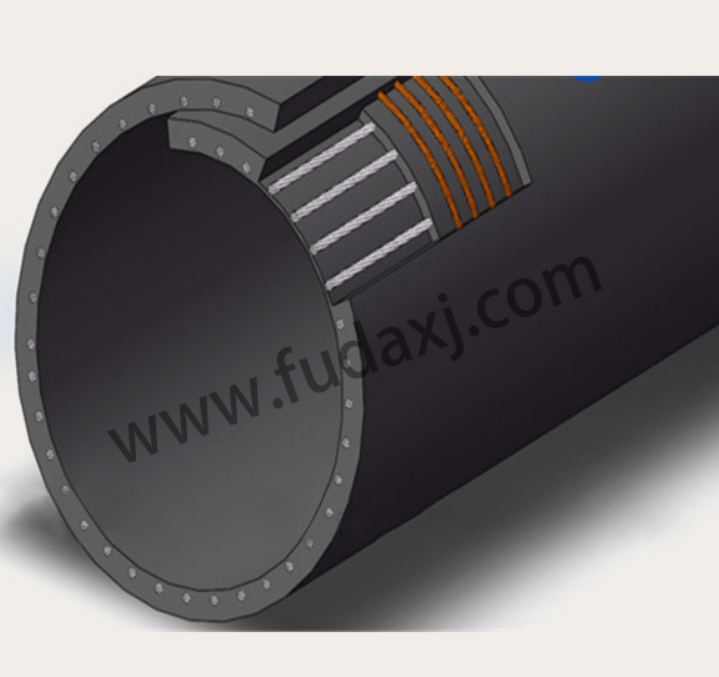

The integration of a steel cord conveyor belt into a bulk material handling system addresses the challenges associated with moving large volumes over extended distances. This type of belt is characterized by its use of steel cables as the primary tensile member, which differentiates it from traditional fabric-ply belts. The application of a steel cord conveyor belt is typically found in sectors where operational demands exceed the capabilities of standard conveyor belts, such as in deep-pit mining, portside ship loading, and cross-country coal transport. The design of a steel cord conveyor belt allows for higher pulling forces and greater impact resistance, which are essential for handling large lumps of material and operating on inclined conveyors. The decision to implement a steel cord conveyor belt is often based on a lifecycle cost analysis that considers its extended service life and reduced maintenance needs. The performance of the steel cord conveyor belt is therefore a key factor in the productivity of large-scale extraction and logistics operations.

Selecting and specifying a steel cord conveyor belt requires a detailed understanding of its technical parameters and the operating environment. The breaking strength of a steel cord conveyor belt, measured in Newtons per millimeter, is a fundamental specification that indicates the maximum tension it can withstand. The selection of the correct steel cord conveyor belt involves matching this breaking strength to the calculated tensions from the conveyor's design, including factors like lift height, belt length, and load weight. The diameter and spacing of the individual steel cords within the steel cord conveyor belt are varied to achieve different strength ratings and flexibility characteristics. The rubber cover grade is another critical selection criterion; for a steel cord conveyor belt handling sharp iron ore, an abrasion-resistant cover is specified, while a belt for transporting copper concentrate might require a cover resistant to chemical degradation. The pulley diameter for the system must also be compatible with the steel cord conveyor belt to avoid causing permanent damage to the steel cords from excessive bending.

The functional benefits of a steel cord conveyor belt translate into tangible operational and economic advantages for large-scale projects. The superior strength of the steel cord conveyor belt enables longer single-flight conveyors, which reduces the number of transfer points. This simplification of the conveyor system lowers capital investment for additional drives and structures and minimizes dust generation and material degradation at transfer stations. The durability of a steel cord conveyor belt often results in a longer operational life compared to fabric belts in similar applications, leading to lower replacement costs and less frequent production interruptions. Its resistance to longitudinal tearing is a significant safety and reliability feature, as a rip in a steel cord conveyor belt is less likely to result in a catastrophic failure that requires immediate shutdown. Furthermore, the predictable elongation behavior of the steel cord conveyor belt allows for more precise and less frequent take-up adjustments, reducing maintenance labor. These collective benefits make the steel cord conveyor belt a cost-effective and reliable choice for the backbone of a major bulk handling system.

The steel cord conveyor belt has established itself as the premier choice for high-tension, long-distance, and heavy-load conveying applications. Its engineering is focused on delivering maximum strength and rip resistance through its unique steel cord reinforcement structure. The operational efficiencies gained through its use, including reduced transfer points and extended service life, provide a compelling value proposition for large-scale industrial operations. As the demand for efficient bulk material transport continues to grow, the role of the robust and reliable steel cord conveyor belt in global infrastructure and resource industries remains firmly secured.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness