Why an IML Mould is a Strategic Investment

In the competitive landscape of plastic packaging, the ability to combine structural integrity with high-quality graphics in a single manufacturing step is a significant advantage, and this is made possible by the IML mould. This specialized tool is engineered to perform the in-mold labeling process, where a decorative film becomes an integral part of the plastic item as it is formed. The decision to invest in an IML mould is a commitment to a production method known for its efficiency and superior output quality. The design phase for an IML mould is collaborative and intricate, involving careful consideration of film handling, plastic flow, and cooling dynamics. Every aspect of the IML mould, from the gate design to the ejection system, is optimized to ensure that the label is perfectly positioned and fused, resulting in a flawless final product straight from the press.

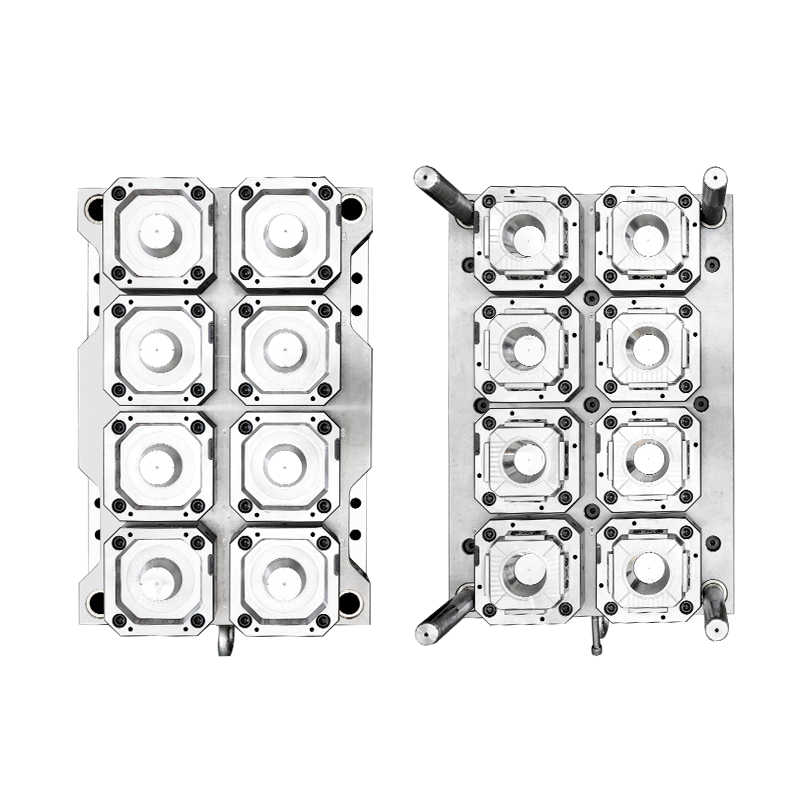

The construction of an IML mould is a multi-stage process that demands a high level of technical skill and advanced machinery. The mold base is typically machined from high-grade steel to endure the rigors of high-volume production. What sets the IML mould apart are the additional components integrated for label handling. This often includes a sophisticated robotic system that is synchronized with the molding machine's cycle to insert the label into the IML mould cavity with repeatable accuracy. The cavity surface of the IML mould may feature micro-perforations connected to a vacuum system that firmly holds the flat film in place against the complex contours of the mold. The precision required in building this system is paramount, as any misalignment in the IML mould can lead to wrinkled labels, incomplete filling, or other visual defects that render the part unacceptable.

The operational benefits afforded by a well-engineered IML mould are compelling for a production facility. The most notable advantage is the consolidation of molding and decoration into a single, automated operation. By using an IML mould, manufacturers eliminate separate, offline processes such as screen printing or the application of pressure-sensitive labels, which reduces overall production time and minimizes handling. This integration leads to a reduction in total cost per decorated part over high volumes, despite the higher initial cost of the IML mould itself. Furthermore, the decorative finish achieved through the IML mould process is exceptionally resilient, as the graphics are encapsulated within the plastic surface, making them resistant to abrasion and chemicals. This durability is a key selling point for products that undergo rough handling, frequent washing, or are used in demanding environments.

The IML mould is a cornerstone of modern decorated plastic part manufacturing, transforming raw plastic and a flat film into a finished, high-value product with unparalleled efficiency. Its creation is a testament to interdisciplinary engineering, combining robotics, thermodynamics, and polymer science. The strategic deployment of an IML mould enables businesses to streamline their operations, enhance the aesthetic and functional quality of their products, and achieve a strong position in markets where packaging and appearance are critical. The ongoing evolution of materials and automation technology will continue to expand the capabilities and applications of the IML mould, ensuring its continued importance in future manufacturing landscapes.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness