The Technical and Safety Benefits of a Low Voltage Motor

The selection of an appropriate drive system is a critical decision in equipment design, and for numerous applications, the Low Voltage Motor presents a compelling solution. Defined by its operation at voltages that are considered safe and readily available, this motor category powers a significant portion of the world's machinery. The term Low Voltage Motor generally encompasses motors that run on standard single-phase or three-phase AC power, such as 230V or 400V, or on DC sources like 24V or 48V. The fundamental appeal of the Low Voltage Motor lies in its direct compatibility with existing electrical grids and control systems without the need for complex and costly voltage transformation equipment. This makes the Low Voltage Motor a practical and economical choice for a diverse range of operational requirements.

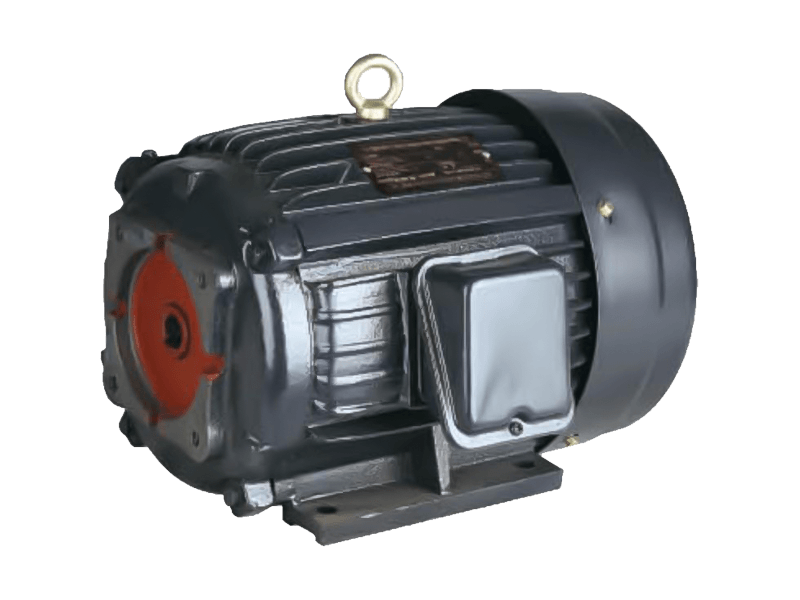

The operational characteristics of a Low Voltage Motor are shaped by its internal design and the principles of electromagnetism. When electrical power is supplied to the motor, it creates a rotating magnetic field in the stator. This field induces currents in the rotor of an induction-type Low Voltage Motor, causing it to turn and produce mechanical shaft power. The efficiency of this energy conversion process is a key performance indicator for any Low Voltage Motor. Manufacturers achieve high efficiency in a Low Voltage Motor through the use of high-quality magnetic steels, optimized winding designs, and reduced electrical losses. The physical construction of a Low Voltage Motor is also designed for durability, with robust bearings and sealed housings that protect internal components from contaminants like dust and moisture, which is essential for maintaining the motor's performance in challenging environments.

From a practical standpoint, the benefits of deploying a Low Voltage Motor are substantial. A primary advantage is enhanced safety for personnel who install, maintain, and operate the equipment. The lower voltage levels of a Low Voltage Motor significantly reduce the risk of severe electrical shock compared to high-voltage systems. Furthermore, the control and protection devices for a Low Voltage Motor, such as contactors, overload relays, and circuit breakers, are widely available, standardized, and cost-effective. The ability to easily connect a Low Voltage Motor to a Variable Frequency Drive (VFD) allows for precise speed control, which can lead to substantial energy savings in applications like pump and fan systems where load requirements vary. This flexibility and the associated operational cost savings make the Low Voltage Motor a strategically sound investment for many businesses.

The Low Voltage Motor is a versatile and strategically important component that effectively balances performance, safety, and cost. Its design is refined for reliable operation within standard electrical frameworks, making it a ubiquitous presence in industrial and commercial settings. The functional and economic advantages of the Low Voltage Motor, including simplified control and reduced electrical hazards, ensure its continued prevalence. As technology progresses, we can expect further refinements in the Low Voltage Motor, particularly in areas of material science for better efficiency and integrated sensors for predictive maintenance, ensuring it remains a fundamental element in the world of mechanical drive systems for the foreseeable future.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness