The Strategic Use of High Damping Rubber in Engineering

In the pursuit of mitigating the effects of vibrations and shocks across various industries, high damping rubber has established itself as a material of great importance. This type of rubber is characterized by its significant internal energy dissipation, a property that distinguishes it from standard elastomeric materials. The primary function of high damping rubber is to reduce the amplitude of oscillations and absorb impact energy quickly, thereby protecting systems and structures from fatigue damage and resonance. The value of high damping rubber lies in its ability to provide this damping effect as an integral property of the material itself, often eliminating the need for additional, complex damping mechanisms. Its implementation is a testament to the application of advanced polymer science to solve practical challenges in dynamics and structural integrity.

The material behavior of high damping rubber is defined by its viscoelastic properties. When deformed, a portion of the energy is stored elastically (like a spring), and a substantial portion is dissipated (damped) due to viscous losses within the material. This damping phenomenon in the rubber is highly dependent on factors such as temperature, frequency of vibration, and the amplitude of strain. Formulators of high damping rubber carefully select base polymers and incorporate specialized additives to create a compound that offers a consistent and effective damping response over a wide range of service conditions. Achieving a high loss factor without compromising the rubber's durability or resistance to environmental degradation like ozone and oxidation is a key objective in producing reliable high damping rubber for long-term applications.

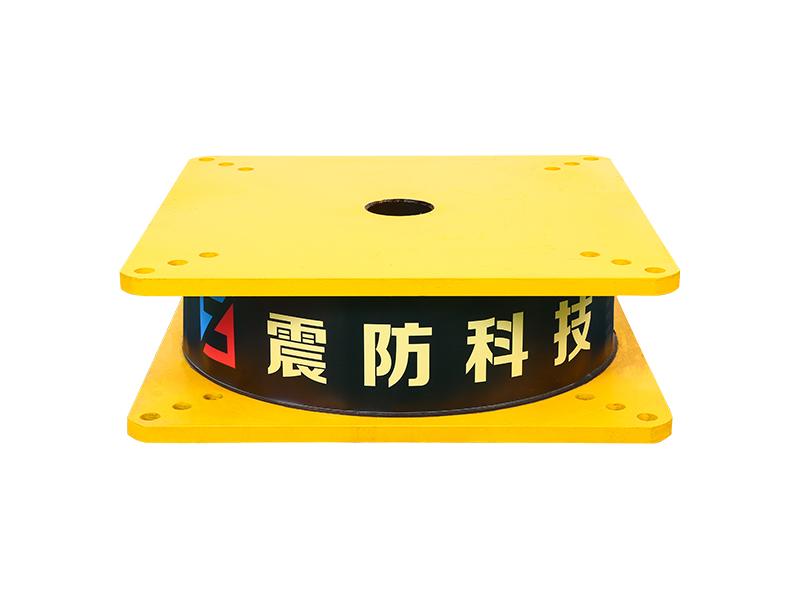

The practical deployment of high damping rubber provides tangible benefits in numerous fields. In railway engineering, pads made from high damping rubber are placed between the rail and the sleeper to dampen vibrations and structure-borne noise, improving the comfort for passengers in nearby buildings and reducing wear on the track components. In building construction, laminated bearings incorporating layers of high damping rubber and steel are used for seismic isolation. The high damping capability of the rubber in these bearings not only isolates the building from ground shaking but also helps to dissipate a large portion of the seismic energy, limiting the sway of the structure. Similarly, in precision manufacturing, equipment mounts made from this rubber prevent ambient floor vibrations from interfering with sensitive machinery, ensuring product quality and operational stability.

High damping rubber is a critically functional material that addresses the universal challenge of unwanted vibrational energy. Its development is rooted in a deep understanding of polymer viscoelasticity and compound engineering. The widespread and successful use of high damping rubber in seismic protection, transportation infrastructure, and industrial applications highlights its effectiveness and reliability. The ongoing research into new polymer blends and nano-scale fillers promises to further enhance the performance and application range of high damping rubber, ensuring it continues to be a key material for engineers focused on creating quieter, safer, and more durable systems and structures. The inherent damping quality of this rubber makes it an indispensable tool in modern engineering.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness