How a Wooden Door Factory Meets Diverse Market Needs

The creation of wooden doors is a detailed process centralized within the operations of a Wooden Door Factory. This manufacturing environment is dedicated to producing a wide array of door products, from simple interior passage doors to elaborate, custom-made exterior entryways. The activities within a Wooden Door Factory encompass a broad spectrum, from the initial cutting of lumber to the final application of a protective finish. The scale of a Wooden Door Factory can vary; some are large facilities producing high volumes of standardized doors for national markets, while others are smaller workshops focusing on artisanal or bespoke pieces. Regardless of size, the core mission of every Wooden Door Factory is to fabricate doors that are durable, functional, and visually appealing, meeting the specific architectural and design needs of their clients.

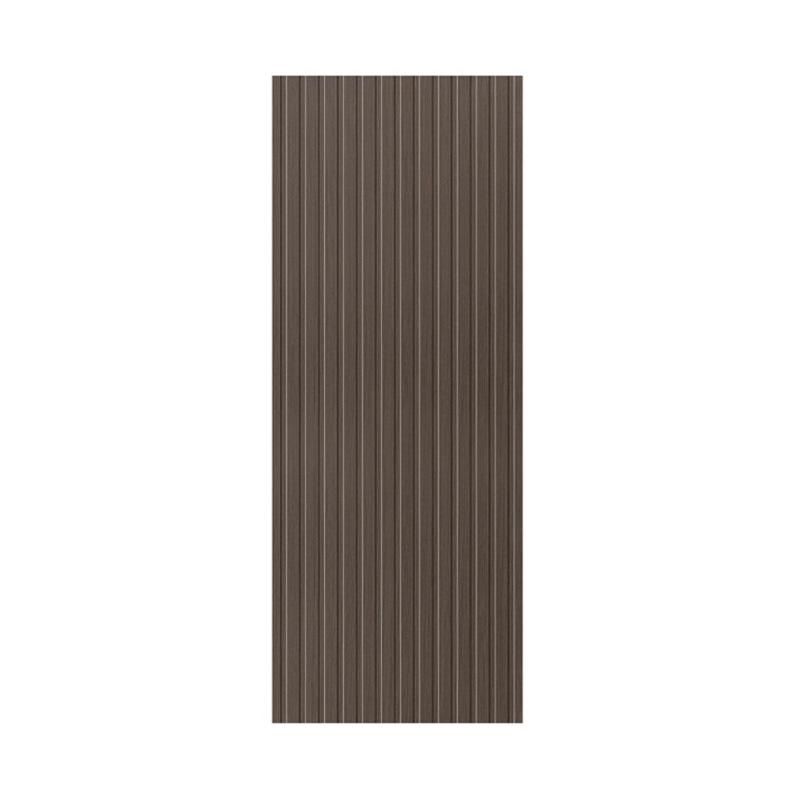

A significant portion of the work in a Wooden Door Factory is dedicated to precision machining and assembly. The factory utilizes a range of equipment, from traditional table saws and routers to computer-numeric-controlled (CNC) machining centers. The CNC machines in a modern Wooden Door Factory are programmed to cut complex joinery, intricate designs, and precise dimensions with a high degree of repeatability. The assembly process in the Wooden Door Factory is where the machined components are brought together. For a typical panel door, this involves gluing and clamping the stiles, rails, and panels. Skilled workers in the factory ensure that the door is square and the joints are tight. The expertise within the Wooden Door Factory is also evident in the finishing department, where craftspeople apply stains, sealers, and paints to enhance the wood's natural beauty and provide protection against the elements.

The strategic value of a Wooden Door Factory extends to its role in the construction supply chain. A reliable factory enables architects, builders, and retailers to source quality door products that align with their project specifications and timelines. The ability of a Wooden Door Factory to offer customization—such as specific dimensions, unique panel designs, or matched stain colors—provides a significant advantage. Furthermore, the factory is a site of continuous improvement, with investments made in sustainable forestry practices, low-VOC finishing materials, and energy-efficient manufacturing processes. The operational efficiency of the Wooden Door Factory directly influences cost structures and delivery schedules, which are critical factors for its business clients. The ability to maintain high quality while scaling production is a key determinant of the Wooden Door Factory's long-term success.

The Wooden Door Factory is a sophisticated production center that plays a critical role in the building materials industry. Its operations require a blend of automated precision and skilled hand-finishing to create products that are both technically sound and stylish. The ability of a Wooden Door Factory to efficiently manage the entire production chain, from raw material to finished door, makes it a key partner for the construction and design sectors. The continued innovation in materials, finishes, and manufacturing techniques within the Wooden Door Factory sector ensures that it can adapt to new architectural trends and environmental standards, securing its essential function in providing a product that combines security, beauty, and craftsmanship.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness