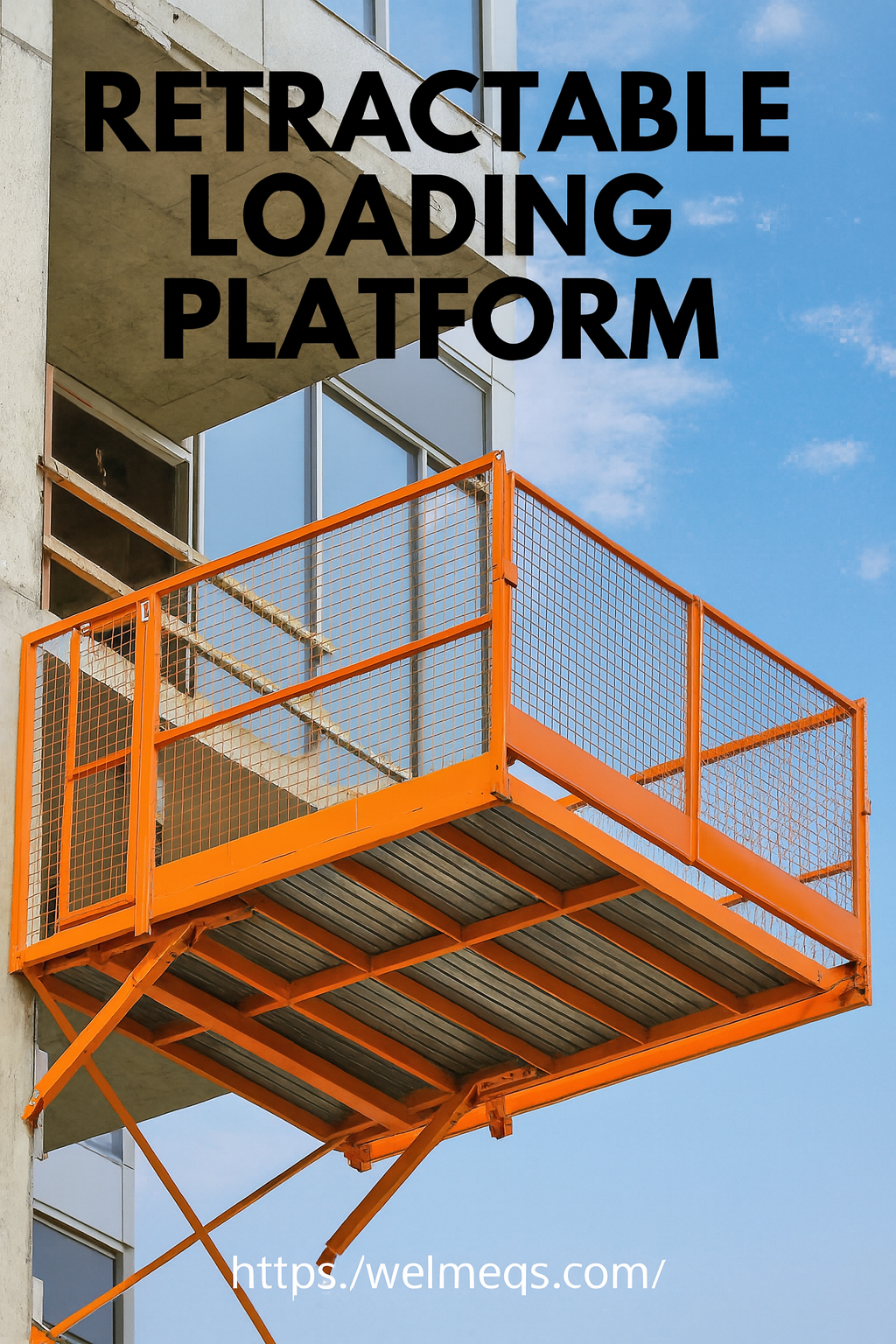

Retractable Loading Platform – The Complete Guide for Safe & Efficient Material Handling

A Retractable Loading Platform plays a vital role in improving safety and efficiency in high-rise construction, industrial operations, and material handling environments. With increasing demand for faster project timelines and safe handling practices, the Retractable Loading Platform has become one of the most essential solutions for lifting and transferring heavy loads. This article explores its design, features, benefits, and applications, ensuring you understand why it is a must-have for modern construction sites.

What Is a Retractable Loading Platform?

A Retractable Loading Platform is a temporary or permanent platform system installed on building floors to facilitate the safe movement of materials using cranes or hoists. The platform extends outward when in use and retracts back into the building structure when not needed. This flexibility helps in optimizing workspace, boosting productivity, and maintaining safety on congested job sites.

The retractable feature makes it highly convenient, especially in projects where multiple floors require material handling without permanent structural changes.

Key Features of a Retractable Loading Platform

1. Sliding or Telescopic Deck

Most Retractable Loading Platform systems are designed with a sliding or telescopic deck that extends smoothly for efficient loading and retracts to save space.

2. High Load Capacity

These platforms are built to carry heavy loads such as steel, formwork, glass, equipment, and construction tools. Many models support capacities from 1,000 kg to over 5,000 kg.

3. Safety Guardrails

To ensure worker safety, guardrails, toe boards, and strong side barriers are installed.

4. Easy Installation

The Retractable Loading Platform can be installed using minimal tools and does not require major structural modifications.

5. Anti-Slip Flooring

Anti-slip flooring reduces the risk of accidents, especially during loading under wet or dusty conditions.

6. Locking Mechanisms

A secure locking system ensures the platform stays stable during loading and lifting.

Benefits of Using a Retractable Loading Platform

✔ Increased Safety

Safety is the biggest advantage. Workers can load materials directly onto a controlled platform instead of leaning cranes over edges or working from unsafe angles. A Retractable Loading Platform stabilizes the load area and minimizes fall risks.

✔ Space Optimization

Construction sites are often congested. Because the platform retracts when not in use, it frees up valuable space for other activities.

✔ Faster Workflow

The Retractable Loading Platform reduces waiting time for crane operators and workers. Materials can be efficiently placed on each floor without delays.

✔ Flexible Material Handling

It supports cranes, forklifts, and hoists for transferring items safely. This flexibility reduces manual labor and improves efficiency.

✔ Reduced Downtime

Since it can be moved or repositioned quickly, downtime is significantly reduced.

How Does a Retractable Loading Platform Work?

The system operates through a sliding mechanism:

-

The platform is mounted on the desired floor level.

-

When needed, the platform deck is pulled outward manually or with hydraulic support.

-

The crane lifts material and places it on the extended platform.

-

After unloading, the deck is pushed back inside, securing it in a locked position.

This simple yet effective mechanism makes the Retractable Loading Platform ideal for fast-paced construction environments.

Applications of Retractable Loading Platforms

1. High-Rise Building Construction

These platforms are widely used for transferring heavy materials to different floors efficiently.

2. Industrial Warehouses

Warehouses use Retractable Loading Platform systems for loading and unloading stock safely.

3. Renovation Projects

Where access is limited, retractable systems help move materials without bringing large equipment inside the building.

4. Manufacturing Plants

Factories use these platforms to receive raw materials and dispatch finished products.

Why Your Project Needs a Retractable Loading Platform

Choosing a Retractable Loading Platform increases project safety, speeds up work, and cuts labor costs. It also ensures compliance with safety regulations by providing a stable platform for lifting and loading operations. Whether you’re handling steel, timber, mechanical equipment, or formwork, this system makes the process smoother, safer, and more organized.

Conclusion

A Retractable Loading Platform is an essential tool for modern construction and industrial operations. Its ability to extend when needed and retract afterward offers both convenience and efficiency. With strong safety features, high load capacity, and flexible applications, it ensures smooth material handling and faster project completion. Investing in a Retractable Loading Platform not only improves productivity but also significantly enhances job-site safety.

If you are working on a construction or industrial project, adding a Retractable Loading Platform is one of the best decisions to improve workflow and ensure worker safety.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness