Technique and Application: Mastering the Use of a Wallboard Saw

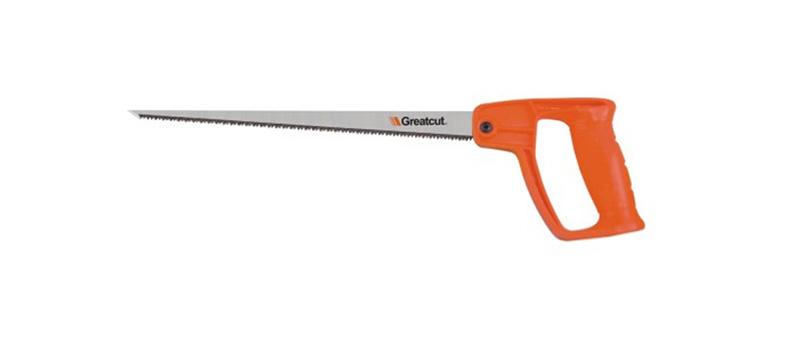

Effective use of a wallboard saw involves more than brute force; it requires an understanding of technique that leverages the tool’s unique design for clean, accurate, and safe results. This specialized saw is not swung like a handsaw but is manipulated with controlled pressure and short strokes, often within the confined space of a marked cutout. Mastery of the wallboard saw centers on the initial puncture, guidance of the blade, and management of the tool’s inherent aggression to avoid damaging unseen elements behind the wall surface. This discussion outlines the procedural knowledge that transforms the wallboard saw from a simple blade into a precise instrument for drywall modification, concluding with a reinforcement of the skill component inherent in wielding this common tool.

The foundational technique with a wallboard saw is the starting puncture. The sharp, spear-point tip must be placed exactly where the cut is intended to begin, typically just inside a marked line for an internal cutout. The user holds the handle firmly, positions the blade perpendicular to the wallboard surface, and applies steady, increasing pressure, often using the palm of the other hand to tap the handle butt. The goal is to drive the tip completely through the drywall’s face paper and gypsum core in one controlled motion, minimizing crushing of the surrounding area. A successful, clean start with the wallboard saw prevents tear-out and establishes a precise entry point for the subsequent cutting work. For cutouts that start at an edge, the wallboard saw’s tip can be inserted directly into the exposed core, bypassing the puncture step.

Once the blade is embedded, the cutting action begins. The user employs short, deliberate strokes, allowing the coarse teeth of the wallboard saw to remove material efficiently. The stiffness of the blade is a key asset here; it helps the user follow the marked line without flexing inadvertently into the area that must remain intact. When cutting longer straight lines, it can be effective to use the wallboard saw with a scoring technique, making multiple shallow passes along the line before cutting fully through, which can yield a cleaner edge on the paper face. For corners, the narrow profile of the wallboard saw blade allows it to pivot within the hole to complete the turn without overcutting.

Safety and awareness are crucial dimensions of using a wallboard saw. Before plunging the tip into any wall, a user must verify the absence of electrical wires, plumbing pipes, or structural members in the immediate cutting zone using a stud finder or by consulting building plans. The aggressive nature of the wallboard saw’s point and teeth means it can easily damage these hidden elements. During the cut, maintaining a firm grip and keeping fingers clear of the blade path is essential, as the tool can jump or slip if it hits an unexpected obstruction. Furthermore, wearing safety glasses is advisable to protect against falling gypsum dust or small debris dislodged by the wallboard saw’s action.

The wallboard saw also plays a role in trimming and modification after initial installation. If a pre-cut opening for a fixture is slightly too small, the wallboard saw is the ideal tool for carefully shaving away excess material to achieve a proper fit. Its pointed tip can be inserted into a gap to begin a trimming cut that would be difficult with a larger saw. Similarly, during repair work, a wallboard saw is used to cut out a neat, geometric section of damaged drywall, creating clean edges that will accommodate a replacement patch seamlessly.

Proficiency with a wallboard saw is a mark of practiced craftsmanship in drywall work. The tool itself is simple, but the techniques governing its use—the controlled puncture, the guided short stroke, the mindful awareness of hidden hazards—elevate its application from mere hacking to precise fabrication. A skilled user understands that the wallboard saw is not just for making holes, but for making prepared openings that facilitate the next step in the construction process. This combination of a dedicated tool and informed technique ensures that the wallboard saw remains an efficient and controlled solution for modifying one of the most common building materials, its effectiveness ultimately determined by the knowledge and care of the person who holds it.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness