Systems Integration: The Management and Protection of Electric Motorcycle Lithium Batteries

A modern electric motorcycle lithium battery pack is a complex integrated system where electrochemical storage capabilities are enabled and safeguarded by advanced electronic and mechanical subsystems. While the lithium-ion cells provide the core energy storage function, their full potential is realized only through meticulous management of their electrical and thermal environment. This integrated approach ensures the electric motorcycle lithium battery delivers reliable power, accepts energy efficiently, and maintains its integrity throughout years of service. The Battery Management System acts as the computational brain, while structural and thermal designs form the protective physical framework. This analysis details how these critical support systems operate in unison to optimize performance, ensure safety, and extend the operational lifespan of the electric motorcycle lithium battery.

The Battery Management System represents the essential intelligence embedded within the electric motorcycle lithium battery pack. This dedicated circuitry performs continuous, high-precision monitoring of every cell group, tracking voltage, current, and temperature. Its primary protective functions are critical: it prevents operation outside safe voltage limits during charging and discharging, a fundamental guard against accelerated degradation or hazardous conditions. The BMS also executes cell balancing, correcting minor capacity variations that naturally develop between cells over time. By redistributing charge, it ensures the entire electric motorcycle lithium battery pack’s capacity is fully utilized, preventing individual weak cells from limiting overall performance. Furthermore, the system calculates real-time estimates for state of charge and state of health, providing accurate data for the vehicle's range display and diagnostic functions.

Thermal management is equally vital for sustaining electric motorcycle lithium battery performance and safety. The electrochemical processes within the cells generate heat, particularly during high-power discharge or rapid charging. Uncontrolled temperature increases can accelerate chemical aging and, in extreme cases, initiate thermal runaway. Effective systems manage this heat through various methods. Passive cooling relies on conductive materials and strategic pack design to dissipate heat into the surrounding structure. More advanced electric motorcycle lithium battery systems may incorporate active thermal management using liquid cooling plates or forced air circulation to maintain an optimal temperature range, ensuring consistent power delivery and enabling repeated fast-charging capability even in demanding conditions.

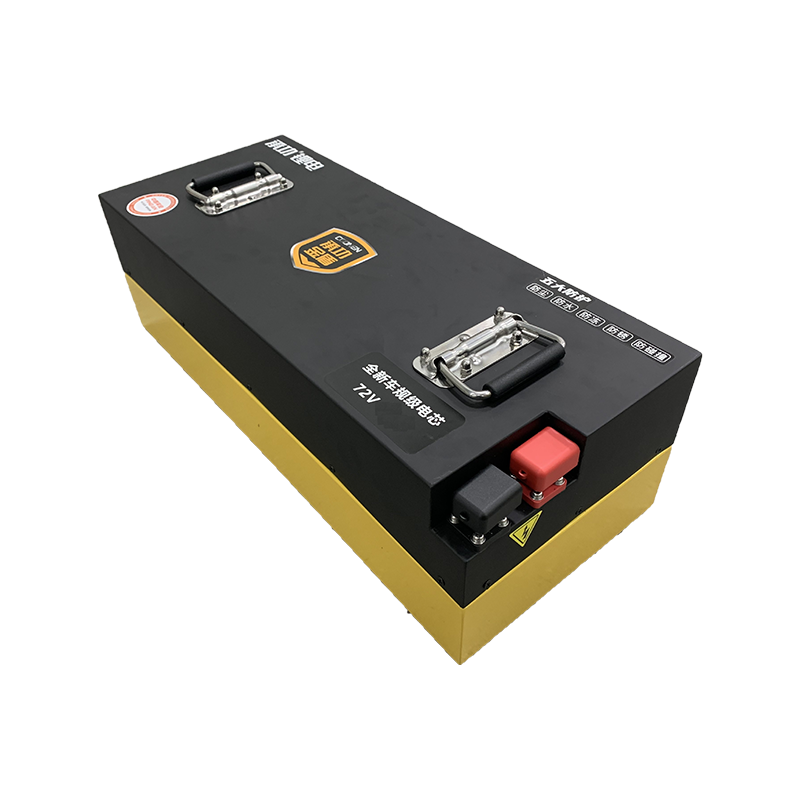

The mechanical packaging of the electric motorcycle lithium battery must fulfill multiple demanding requirements. The enclosure provides crucial structural rigidity, protecting the delicate internal cells from vibration, impact, and environmental contaminants like moisture and dust. It also plays a role in thermal dynamics, acting as a heat sink or interface for cooling systems. Electrical safety is engineered into the design with robust isolation, properly rated high-current connectors, and integrated fuse or contactor protection. The physical form factor and mounting strategy of the electric motorcycle lithium battery pack are also key vehicle design considerations, influencing chassis geometry, weight distribution, and overall center of gravity.

The intelligence embedded within the electric motorcycle lithium battery is poised for further advancement. Predictive algorithms could analyze usage patterns and cell data to forecast aging and optimize charging protocols individually. Enhanced communication with charging infrastructure and smart grids will enable more efficient energy management. These developments will make the electric motorcycle lithium battery not merely an energy container, but an adaptive, communicative component of a larger mobility ecosystem.

The performance and longevity of an electric motorcycle lithium battery are direct outcomes of its supporting systems. The seamless interaction between vigilant electronic management, deliberate thermal control, and robust mechanical design transforms raw electrochemical potential into safe, dependable, and high-performing vehicle propulsion. For riders and manufacturers, appreciating this integrated complexity is key to understanding the value, capabilities, and proper care of these power systems. The ongoing refinement of these ancillary systems will continue to push the boundaries of what is achievable, ensuring the electric motorcycle lithium battery remains a reliable and technologically progressive cornerstone of electric mobility.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness