Anatomy of a Submersible Pump: Key Components and Construction

The reliability and performance of a submersible pump are direct results of its robust internal engineering, designed to withstand continuous operation in a demanding, submerged environment. Every component, from the outer shell to the smallest seal, is specified to prevent water ingress, resist corrosion, and manage the hydraulic and electrical loads. Understanding the anatomy of a submersible pump reveals why it can operate reliably for years at significant depths while being inaccessible for daily inspection. This analysis breaks down the primary subsystems of a typical submersible pump, explaining the function and design challenges of each, concluding that its durability is a product of integrated, purpose-built engineering.

The waterproof motor is the power source and a critical engineering feat. Unlike standard motors, the motor in a submersible pump is completely sealed. It is often a squirrel-cage induction type, filled with a thin dielectric oil. This oil serves multiple purposes: it lubricates the bearings, transfers heat from the motor windings to the motor housing, and provides internal pressure that helps balance the external water pressure, reducing stress on the seals. The stator windings are insulated with special waterproof materials. The shaft is supported by bearings designed for long life in a lubricated environment. The entire motor unit is encapsulated within a thick-walled, corrosion-resistant housing, forming the lower section of the submersible pump assembly.

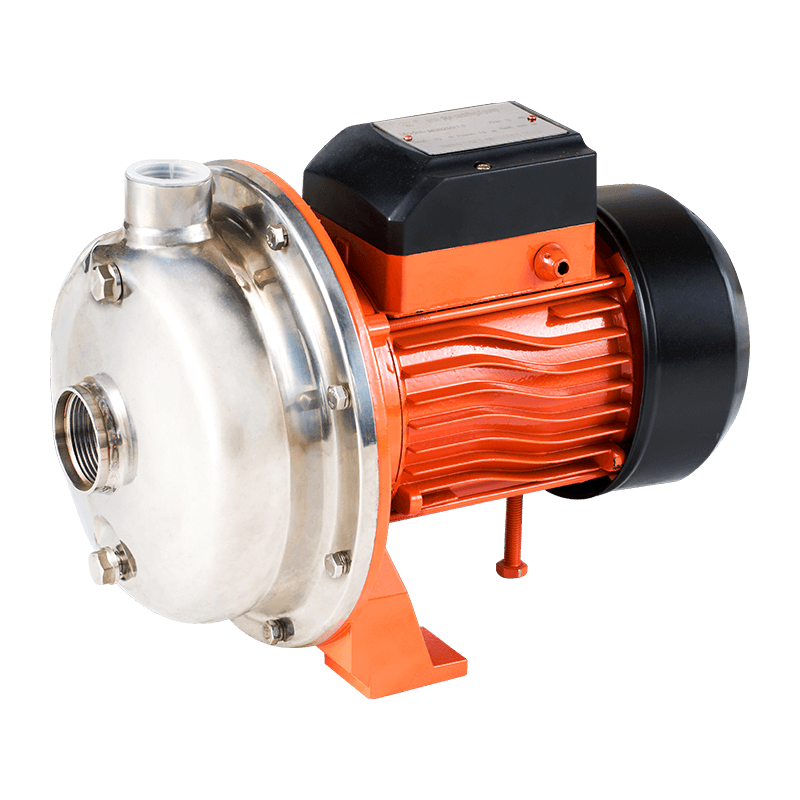

Directly above the motor is the pump section. In a centrifugal submersible pump, this consists of a stack of impellers and diffusers. Each impeller-diffuser pair constitutes a stage. The number of stages in a submersible pump determines the total head (pressure) it can generate. The impellers are fixed to the motor shaft and rotate at high speed, imparting kinetic energy to the fluid. The stationary diffusers surrounding each impeller convert this velocity into pressure and direct the flow to the inlet of the next stage. The materials for these components vary; bronze or stainless steel is common for clean water, while hardened alloys or specialized plastics may be used for abrasive or corrosive fluids in an industrial submersible pump.

The sealing system is arguably the most vital subsystem, acting as the barrier between the wet pump end and the dry motor compartment. A submersible pump typically employs multiple mechanical seals arranged in series. These seals consist of very flat, polished faces—one rotating with the shaft, one stationary—that are spring-loaded to maintain contact. They create a watertight barrier that allows the shaft to spin. Often, an additional labyrinth seal or lip seal is used as a first line of defense against sand and grit. The cable entry point is another critical seal, using a compression gland or a molded, potted connection to ensure no water travels along the power conductors into the motor of the submersible pump.

Additional components include a intake screen to keep large debris out, a check valve to prevent backflow and water hammer when the pump stops, and a thermal overload protector within the motor to prevent burnout.

A submersible pump is a masterclass in packaging and protecting sensitive electromechanical systems for a hostile environment. Its design is a holistic response to the challenges of pressure, corrosion, and continuous duty. Therefore, the quality of a submersible pump is intrinsically linked to the quality of its motor insulation, the precision of its mechanical seals, and the durability of its hydraulic components. When these elements are engineered and assembled to a high standard, the submersible pump becomes a remarkably dependable asset, capable of operating unattended for long periods, pushing fluids from depths that would challenge any other pump type. Its integrated construction is its greatest strength, making the modern submersible pump a compact and powerful solution for submerged pumping duties.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness