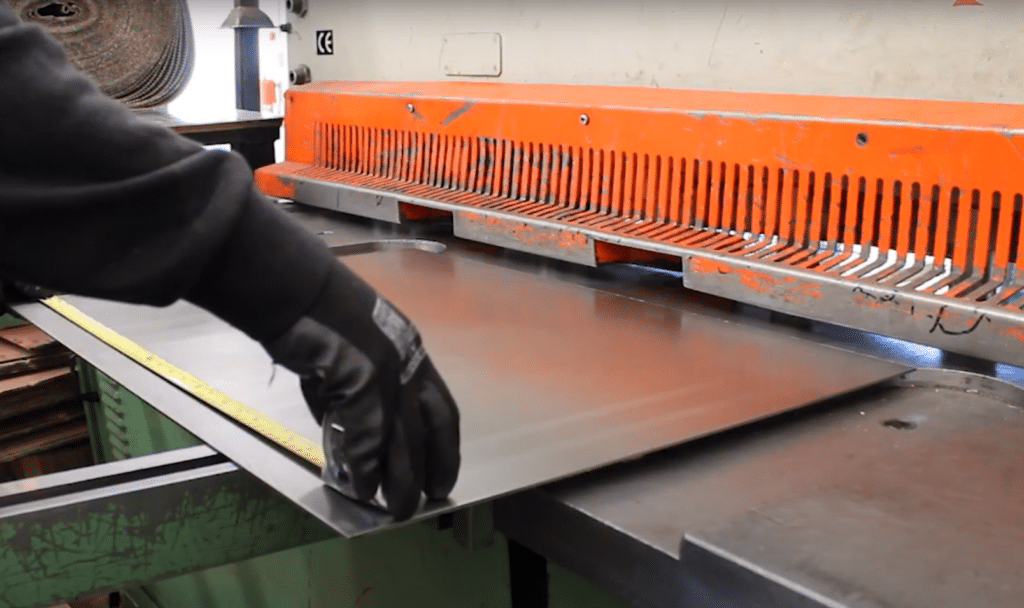

Guillotine Machine Maintenance Tips for Longer Life

A guillotine machine is an essential tool in many industries, from metal fabrication to paper cutting. Like any high-precision equipment, regular maintenance is critical to ensure it operates safely and efficiently. Whether you own a guillotine machine or are considering guillotine machine hire, following proper maintenance practices can extend its lifespan and save costs over time.

1. Regular Cleaning is Key

Dust, debris, and scrap materials can accumulate on the blades and moving parts of a guillotine machine, reducing cutting precision. Clean the machine daily or after heavy use using a soft brush or air compressor. Avoid harsh chemicals that can damage metal surfaces.

Pro Tip: Pay special attention to the blade area and guides, as accumulated debris can lead to uneven cuts or blade damage.

2. Lubricate Moving Parts

Lubrication is vital for smooth operation. Use machine oil or grease recommended by the manufacturer on all moving parts, including the slide rails, gears, and blade mechanism.

Tip for Hire Machines: If you are opting for guillotine machine hire, check whether the equipment has been regularly lubricated by the provider to avoid operational issues.

3. Inspect Blades Regularly

The blade is the heart of a guillotine machine. Dull or damaged blades can cause poor cutting quality and increase strain on the machine. Inspect the blade weekly for nicks, bends, or wear and sharpen or replace it as needed.

Safety Note: Always follow safety protocols while handling blades—wear protective gloves and disconnect power before inspection.

4. Check Alignment and Calibration

Misaligned blades or guides can reduce cutting accuracy and put unnecessary stress on the machine. Regularly check blade alignment and recalibrate according to the manufacturer’s instructions.

Hiring Tip: When you choose guillotine machine hire, ensure the machine has been properly calibrated before starting work.

5. Monitor Hydraulic and Electrical Systems

For hydraulic or electrically operated guillotine machines, regularly inspect hydraulic fluid levels, hoses, and electrical wiring. Replace worn parts promptly to prevent downtime and costly repairs.

6. Schedule Professional Maintenance

Even with regular self-maintenance, it’s a good idea to schedule professional servicing periodically. Manufacturers or hire companies often provide maintenance services, which can help prolong the life of your machine and ensure optimal performance.

7. Proper Storage and Usage

Avoid overloading the guillotine machine, and always use it within the recommended specifications. When not in use, store the machine in a dry, clean environment to prevent rust and corrosion.

Conclusion

Proper care of your guillotine machine ensures precise cuts, reduces downtime, and extends the machine’s lifespan. Even if you are using a guillotine machine hire service, following these maintenance tips can help you operate the equipment safely and efficiently. Regular cleaning, lubrication, blade inspection, and professional servicing are the pillars of long-lasting performance.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness