Engineering the Vessel: Design and Features of Reaction Kettles

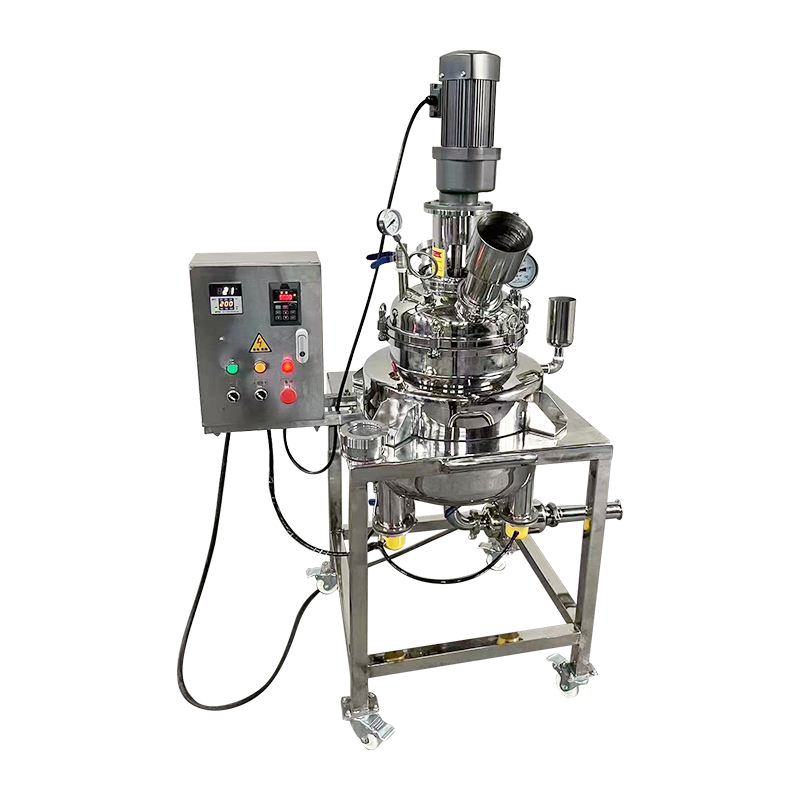

The effectiveness and safety of a reaction process are directly influenced by the specific engineering choices made in constructing the reaction kettle. This vessel is not a generic tank but a custom-engineered system where materials, agitation design, heat exchange capability, and safety features are specified based on the chemical process it will host. Understanding these design variables—from the metallurgy of the vessel wall to the type of mechanical seal—explains how a reaction kettle is optimized for a particular duty, whether it involves corrosive acids, high-pressure hydrogenation, or sterile pharmaceutical production. This analysis delves into the critical design aspects that define a reaction kettle's capabilities and limitations, concluding that its engineering is a precise response to process requirements.

Material selection is the foremost consideration for the reaction kettle body and internal components. The choice hinges on chemical compatibility, temperature range, and required cleanliness. For general chemical service, 304 or 316L stainless steel is common. For highly corrosive environments (e.g., involving chlorides or strong acids), more resistant materials like Hastelloy, titanium, or glass-lined steel are used. A glass-lined reaction kettle offers excellent corrosion resistance for a wide pH range, though it can be susceptible to thermal and physical shock. The interior surface finish is also specified; a polished or electropolished finish on a stainless steel reaction kettle minimizes adhesion and eases cleaning, which is critical for batch-to-batch purity in industries like pharmaceuticals.

The agitation system design is process-specific. The agitator shaft can enter from the top or, less commonly, from the bottom of the reaction kettle. The selection of impeller type—such as a Rushton turbine for gas dispersion, a pitched-blade turbine for axial flow, or an anchor/scraper agitator for high-viscosity materials—directly affects mixing performance. The power of the drive motor and the gearbox must be sufficient to agitate the reaction mass at its highest predicted viscosity. The sealing system where the agitator shaft penetrates the reaction kettle is critical; a single or double mechanical seal prevents leaks of process materials, with options for flush systems to lubricate the seal faces or keep crystallizing materials away from them.

Heat transfer design is another core engineering function. While a simple jacket is standard, various enhancements exist. A half-pipe coil jacket provides higher pressure ratings and better heat transfer coefficients for demanding temperature control. Internal coils may be installed inside the reaction kettle for additional heat transfer area, though they can complicate cleaning. For precise exothermic reaction control, the jacket may be connected to a cascade temperature control system. The working pressure and temperature rating of the reaction kettle vessel and jacket are calculated based on process safety studies, determining wall thickness and necessitating compliance with pressure vessel codes. All nozzles, manways, and supports are designed to handle these operational stresses.

A reaction kettle is a sophisticated piece of process equipment where mechanical design is dictated by chemical process needs. Its construction involves a series of deliberate choices regarding corrosion resistance, mixing dynamics, thermal management, and pressure containment. Therefore, specifying a reaction kettle requires a detailed understanding of the process chemistry, including all phases of the reaction cycle. A well-engineered reaction kettle provides a reliable, safe, and efficient environment that enables consistent product quality, minimizes downtime for maintenance, and protects both the process and the operators, demonstrating that its design is a direct investment in process integrity and operational success.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness