Advancing Design in Yogurt Cup Injection Mould Technology

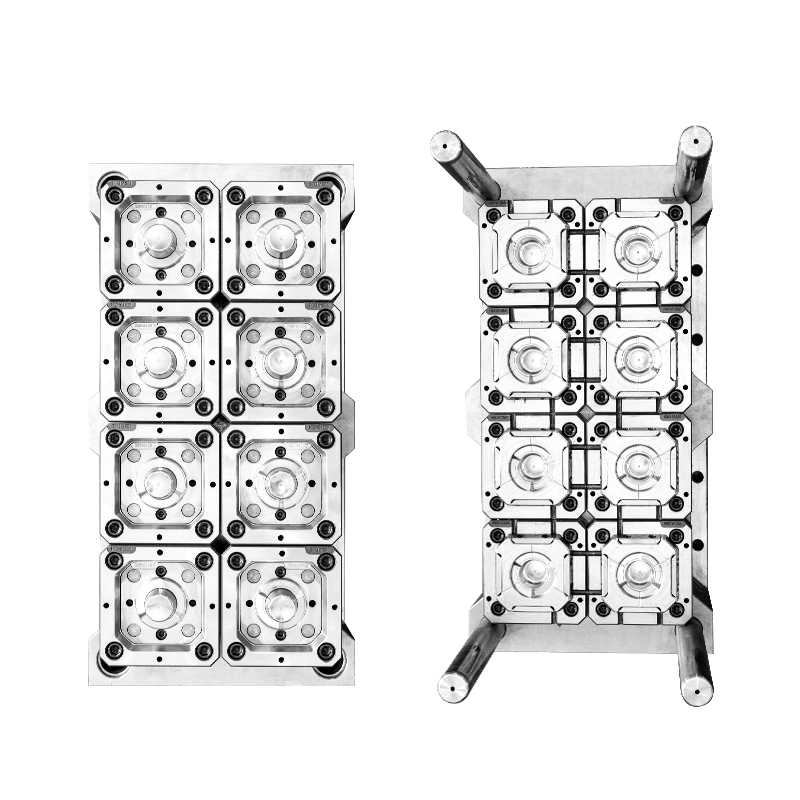

In the dynamic field of food packaging, continuous innovation is essential, and much of this progress is driven by advancements in the yogurt cup injection mould. This tool has evolved from a simple shaping device into a sophisticated system engineered for peak efficiency, material conservation, and enhanced functionality. Modern development of the injection mould for yogurt cups focuses on overcoming key challenges: reducing cycle times to boost output, minimizing plastic usage without compromising strength, and enabling the use of new, more sustainable polymer blends. These goals are achieved through innovative approaches to mould design, including advanced cooling geometries, novel surface engineering, and intelligent process integration. Consequently, the contemporary yogurt cup injection mould serves as a platform for implementing responsible manufacturing practices and responding to market demands for improved environmental performance and product differentiation.

A primary focus for innovation is the thermal management system within the yogurt cup injection mould. Traditional straight-line cooling channels are being supplemented or replaced by conformal cooling circuits. These are channels, often created through additive manufacturing (3D printing), that follow the exact contours of the mould cavity and core. This design allows for much more uniform and efficient heat extraction from the solidified plastic. A yogurt cup injection mould with an optimized conformal cooling system can significantly shorten the cooling portion of the cycle, enabling faster production speeds and lower energy consumption per cup. This directly translates to higher factory output and a reduced carbon footprint for each unit produced, showcasing how mould design directly impacts operational sustainability.

The industry-wide push for source reduction is profoundly influencing yogurt cup injection mould engineering. The process of lightweighting—designing cups to use less material while maintaining performance—places extreme demands on the injection mould. It requires exceptional precision in cavity dimensions and perfect control over material flow and packing to ensure ultra-thin walls are filled completely and have sufficient rigidity. Additionally, moulds are being adapted to process an increasing variety of materials, including post-consumer recycled (PCR) content and bio-based polymers. These alternative resins can have different flow characteristics and shrinkage rates than virgin plastics, necessitating that the yogurt cup injection mould be designed with broader processing windows and potentially modified gating systems to ensure consistent, high-quality results from variable feedstocks.

Another area of development is the integration of smart systems directly into the yogurt cup injection mould. Sensors can be embedded to monitor real-time conditions such as cavity pressure, temperature at critical points, and cooling line efficiency. This data enables closed-loop process control, where the injection moulding machine can make automatic micro-adjustments to parameters like injection speed or pressure for each cycle. This level of control maximizes consistency, minimizes the production of off-specification cups (reducing waste), and provides valuable insights for predictive maintenance of the mould itself. By turning the injection mould into a data-generating component, manufacturers gain unprecedented oversight and optimization capabilities over the entire forming process.

The modern yogurt cup injection mould is a dynamic instrument of progress in packaging manufacturing. Its evolution is marked by a shift towards intelligent, efficient, and adaptable systems that do more than just shape plastic. Through breakthroughs in cooling technology, support for innovative materials, and the incorporation of Industry 4.0 sensors, the injection mould is actively helping producers achieve goals of speed, resource efficiency, and quality assurance. As these technologies mature, the future yogurt cup injection mould will likely become even more central to creating packaging that is not only functional and cost-effective but is also produced through a smarter, more responsive, and less wasteful manufacturing paradigm.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness