The Role of Advanced Software in Modern Laser Engraving Systems

With the rapid development of laser processing technology, hardware performance alone is no longer enough to meet the growing demands of precision manufacturing. Today, engraving machine software plays a critical role in determining engraving accuracy, production efficiency, and overall system stability.

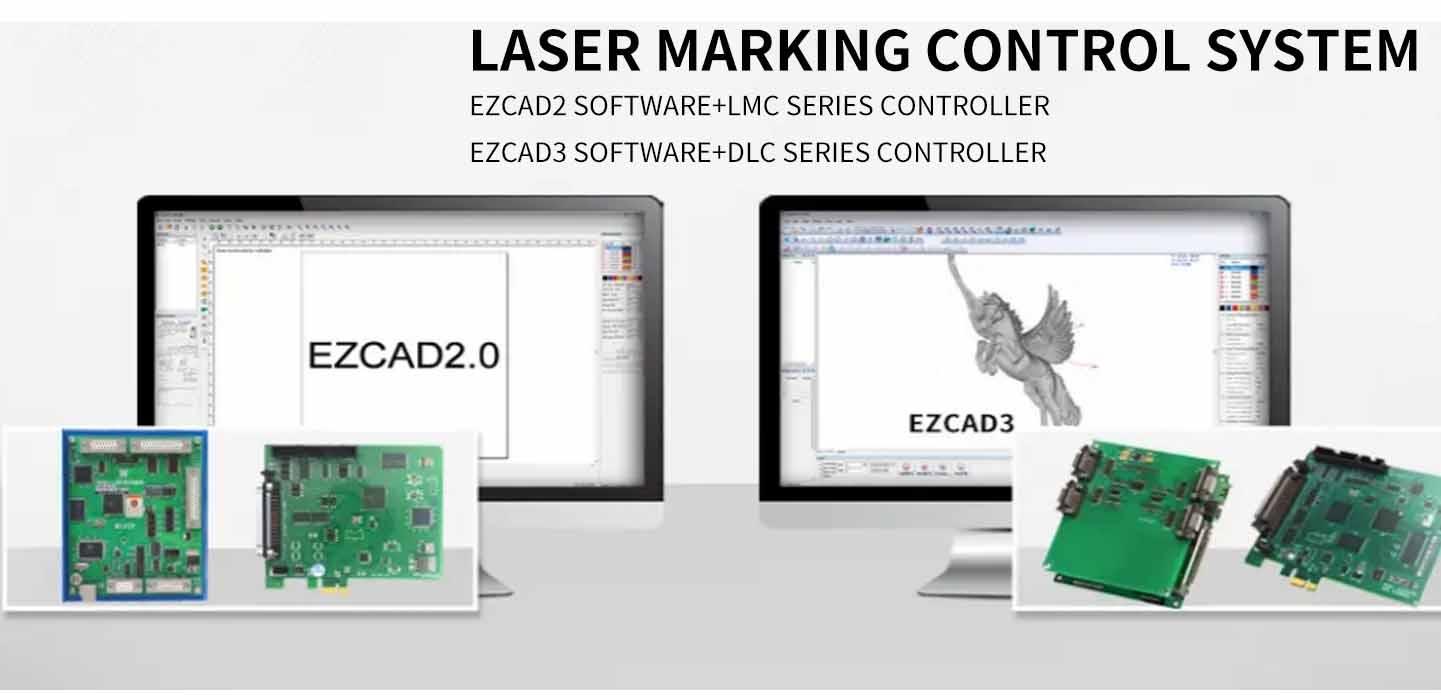

Modern laser engraving systems rely heavily on intelligent control platforms that integrate design, parameter management, and real-time motion control. As a result, laser engraver control software has become the core component connecting laser sources, galvo scanners, and industrial automation systems.

Why Engraving Machine Software Matters More Than Ever

Unlike traditional mechanical engraving, laser engraving requires precise coordination between laser power, scanning speed, and motion control. High-quality engraving machine software enables operators to fine-tune processing parameters for different materials, ensuring consistent engraving quality across various applications.

Key advantages include:

-

Centralized parameter control for different materials

-

High-speed data processing and stable signal output

-

Real-time monitoring and error prevention

-

Improved repeatability for mass production

Without reliable laser engraver control software, even the most advanced laser hardware cannot achieve optimal performance.

Laser Engraver Control Software for Industrial Automation

In industrial environments, production efficiency and system stability are top priorities. Professional laser engraver control software supports seamless integration with fiber, CO₂, UV, and green laser systems, allowing manufacturers to handle complex marking and engraving tasks with ease.

Advanced control software often supports:

-

Vector and bitmap file import

-

Multi-layer processing and marking sequences

-

Automation interfaces for production lines

-

Compatibility with major galvo and motion control systems

These features make laser engraver control software essential for scalable and automated manufacturing solutions.

Fiber Laser Marking Software for Precision Metal Processing

For metal engraving applications, fiber laser marking software is specifically optimized to manage high-speed marking and deep engraving processes. It allows precise control over pulse frequency, power modulation, and scanning paths, ensuring clean and permanent marks on metal surfaces.

Typical applications of fiber laser marking software include:

-

Serial number and barcode marking

-

Deep engraving on stainless steel and aluminum

-

High-contrast black marking on metal

-

Traceability solutions for industrial parts

Reliable fiber laser marking software helps manufacturers maintain consistent quality while reducing material waste and downtime.

Software Compatibility and User Experience

Ease of use and system compatibility are increasingly important in today’s competitive manufacturing landscape. Modern engraving machine software is designed with intuitive interfaces, multi-language support, and flexible configuration options to reduce operator training time.

At the same time, professional laser engraver control software ensures long-term system stability through continuous updates, hardware compatibility, and robust error-handling mechanisms. This balance between usability and performance is key to successful laser processing operations.

Future Trends in Laser Engraving Software

As smart manufacturing and Industry 4.0 continue to evolve, fiber laser marking software and other laser control platforms are becoming more intelligent. Features such as remote monitoring, data analysis, and automated parameter optimization are gradually becoming industry standards.

Manufacturers who invest in advanced engraving machine software gain a competitive advantage by improving production efficiency, reducing operating costs, and achieving higher-quality marking results.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness