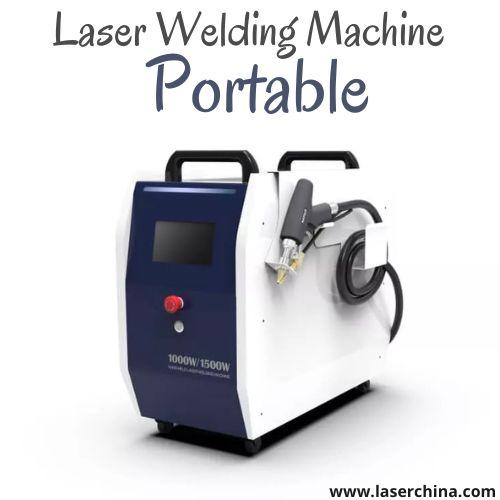

Laser Welding Machine Portable for Modern Precision Metal Fabrication

The laser welding machine portable has become a defining presence in modern metal fabrication environments where precision, mobility, and refined workmanship are essential. This category of welding equipment represents a shift from fixed, heavy industrial systems toward flexible solutions that align with contemporary production demands. By combining compact construction with advanced laser technology, the laser welding machine portable fits seamlessly into workshops, factories, repair facilities, and on-site operations that require consistent and controlled welding results.

In many manufacturing sectors, space efficiency and workflow adaptability play a critical role. A laser welding machine portable addresses these expectations by offering a streamlined approach to welding tasks without the need for large-scale installations. Its compact footprint allows it to be transported easily across different work areas, making it suitable for both permanent facilities and temporary job sites. This mobility supports a dynamic production environment where tasks vary daily and rapid setup is necessary.

The working principle of a laser welding machine portable revolves around concentrated laser energy applied to join metal components with high accuracy. The laser beam focuses on a specific area, generating localized heat that melts and fuses materials together. This controlled energy application enables operators to work with a wide range of metal thicknesses and joint types. The precision of laser welding ensures clean seams and consistent results, which is why this technology has become increasingly common in industries that prioritize refined craftsmanship.

Manufacturing workshops that deal with custom fabrication often rely on equipment that can adapt quickly to changing project requirements. A laser welding machine portable fits naturally into such environments, supporting short production runs, customized metal parts, and intricate assemblies. The ability to move the machine close to the workpiece reduces handling time and simplifies workflow organization. This adaptability enhances overall productivity without compromising the quality of welded joints.

In the automotive sector, the laser welding machine portable is frequently used for repair, assembly, and component modification tasks. Its precise control allows technicians to work on thin metal panels, brackets, and structural elements with accuracy. The compact design makes it practical for service centers where space is limited and multiple tasks must be completed efficiently. From restoring damaged components to assembling specialized parts, portable laser welding solutions integrate smoothly into automotive workflows.

The aerospace industry also recognizes the value of portable laser welding systems, particularly for maintenance and component fabrication tasks. Aircraft parts often require exact tolerances and consistent weld quality. A laser welding machine portable enables technicians to perform detailed welding operations in controlled environments without relocating sensitive components. This approach supports strict quality standards while maintaining flexibility in maintenance and manufacturing operations.

In the field of electronics and electrical equipment manufacturing, precision is a defining requirement. Small metal housings, connectors, and structural supports benefit from the controlled welding process offered by a laser welding machine portable. The focused laser beam allows for accurate joining of delicate components without excessive heat spread. This level of control is essential when working with compact assemblies where traditional welding methods may be less suitable.

The construction and metal fabrication industries increasingly incorporate portable laser welding solutions into their operations. On-site fabrication, structural adjustments, and customized installations often require welding equipment that can be transported easily. A laser welding machine portable supports these tasks by allowing operators to perform welding work directly at the installation site. This reduces the need for transporting large metal structures back and forth, streamlining project timelines.

Artistic metalwork and custom design studios also find value in laser welding technology. Sculptors, designers, and metal artists often work with complex shapes and fine details that demand accuracy. A laser welding machine portable provides the control needed to join artistic elements cleanly, supporting creative expression while maintaining structural integrity. Its adaptability allows artists to experiment with various metals and designs without being constrained by fixed equipment.

In industrial maintenance and repair operations, downtime reduction is a priority. A laser welding machine portable supports quick response to equipment wear, cracks, or component failure. Maintenance teams can bring the machine directly to the affected area, performing precise repairs without dismantling entire systems. This approach aligns with modern maintenance strategies focused on efficiency and minimal disruption.

Training and technical education facilities also incorporate portable laser welding systems into their programs. Students learning advanced welding techniques benefit from hands-on experience with modern equipment. A laser welding machine portable fits well into educational settings where flexibility and safety are important. Instructors can demonstrate welding processes across different workstations, allowing learners to observe and practice under controlled conditions.

The integration of a laser welding machine portable into production environments reflects a broader trend toward smart manufacturing. Modern workshops emphasize efficiency, accuracy, and adaptability. Portable laser welding systems align with these goals by offering a balance between advanced technology and practical usability. Their presence supports lean manufacturing principles, where equipment must contribute directly to streamlined operations.

From small-scale workshops to large industrial facilities, the laser welding machine portable adapts to diverse operational needs. Its design allows it to complement existing machinery without requiring extensive modifications to the workspace. This compatibility makes it an appealing option for businesses looking to modernize their welding capabilities while maintaining operational continuity.

As global manufacturing standards continue to evolve, the demand for precise and adaptable welding solutions grows. The laser welding machine portable stands out as a response to these changing expectations. Its application across multiple industries highlights its versatility and relevance in today’s competitive production landscape. Whether used for fabrication, repair, customization, or education, this technology represents a modern approach to metal joining.

The growing presence of portable laser welding equipment in international markets reflects its alignment with current industrial priorities. Manufacturers seek solutions that support efficiency, quality consistency, and operational flexibility. A laser welding machine portable addresses these priorities by combining advanced laser technology with a form factor designed for real-world use.

In workshops focused on innovation and continuous improvement, the laser welding machine portable serves as a practical tool that supports evolving production strategies. Its role extends beyond simple welding tasks, contributing to optimized workflows, refined craftsmanship, and adaptable manufacturing processes. As industries continue to adopt advanced fabrication methods, portable laser welding systems remain an integral part of modern metalworking environments.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness