How a Mould Factory Adapts to Complex Project Requirements

The capabilities of a modern injection mould factory extend far beyond basic machining, encompassing a range of advanced engineering solutions to meet diverse and demanding project requirements. A key differentiator is the factory's expertise in various mould technologies. This includes standard two-plate moulds, more complex three-plate moulds for automated part separation, and intricate family moulds that produce multiple different parts in a single cycle. Furthermore, an advanced injection mould factory will have extensive experience with hot runner systems. These systems maintain the plastic in a molten state within the mould, eliminating material waste from cold runners and allowing for more complex gating and faster cycle times. The integration of such systems requires additional design foresight and precision machining from the injection mould factory.

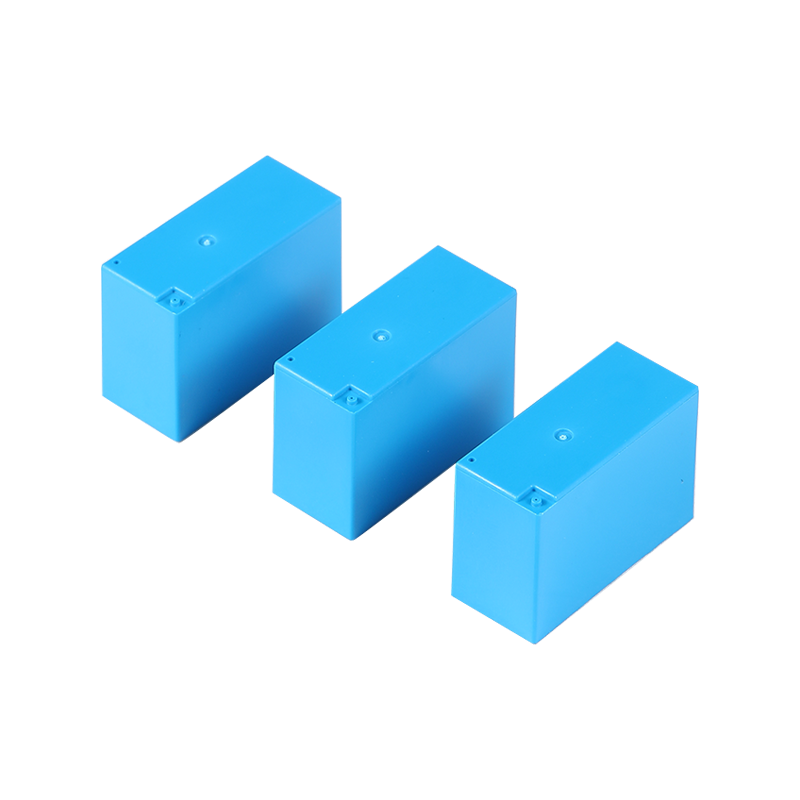

Handling projects with high complexity is a hallmark of a proficient injection mould factory. This involves designing and building moulds with actions like slides, lifters, and unscrewing mechanisms to form undercuts and internal threads. The factory's engineering team must devise robust mechanical or hydraulic systems within the mould structure to create these complex geometries and reliably retract them before part ejection. Material science knowledge is also essential. An injection mould factory must select the appropriate grade of tool steel—such as P20, H13, or stainless steel—based on the plastic resin to be used, expected production volume, and required surface finish. For high-gloss parts, like automotive lenses or consumer electronics housings, the factory's polishing technicians must achieve a mirror-like finish on the steel cavity surfaces, a skill that significantly impacts the final product's appearance.

To stay competitive, a forward-looking injection mould factory invests in continuous technological advancement. This includes software for advanced mould flow analysis, simulating how plastic will fill and cool within the mould to predict and prevent defects before manufacturing begins. The adoption of additive manufacturing, or 3D printing, allows for the creation of conformal cooling channels. These channels follow the contour of the mould cavity more closely than drilled straight lines, enabling vastly improved cooling efficiency, which reduces cycle times and improves part quality. Additionally, many factories offer value-added services such as product design for manufacturability consultations, helping clients optimize their part designs for the injection moulding process before the mould design is finalized. By integrating these advanced capabilities, an injection mould factory positions itself not just as a tool maker, but as a comprehensive engineering partner capable of solving complex manufacturing challenges and delivering a mould that ensures efficient, high-quality production for its client.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness