The Essential Mechanics Behind a Standard Conveyor Belt System

A conveyor belt is a continuous loop of material that rotates around two or more pulleys, used to transport objects from one location to another with minimal human effort. It is a fundamental component in modern material handling, forming the backbone of logistics, manufacturing, and processing operations worldwide. The primary purpose of a conveyor belt is to provide a moving surface that carries items efficiently over fixed paths. The basic system consists of the belt itself, which acts as the carrying medium, a drive pulley powered by a motor that provides the motion, a tail or return pulley at the opposite end, and a series of idler rollers that support the belt along its length. The continuous nature of the conveyor belt allows for the uninterrupted flow of materials, significantly increasing throughput compared to manual or batch transportation methods.

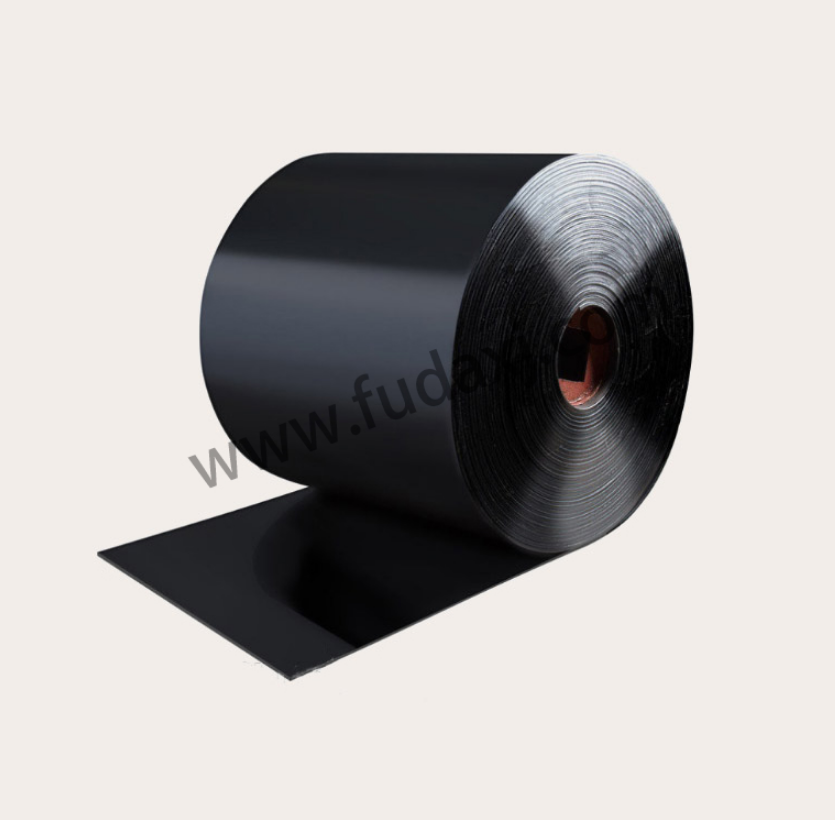

The construction of a typical conveyor belt is a multi-layered assembly designed for strength and durability. The central layer is the carcass, which provides the tensile strength necessary to handle the load and transmit the driving force. This carcass is usually made from fabrics like polyester, nylon, or cotton, or from steel cords for heavy-duty applications. On top of this reinforcement, layers of rubber or various polymer compounds are applied to form the covers. The top cover of the conveyor belt is the working surface that directly contacts the material being conveyed; it is formulated to resist wear, abrasion, and sometimes chemicals or oils. The bottom cover protects the carcass from moisture and friction against the idlers. The edges of the conveyor belt are also critical, often reinforced to prevent damage and fraying.

The operation of a conveyor belt system is governed by simple mechanical principles. An electric motor drives the head pulley, creating friction that pulls the belt forward. The tension in the conveyor belt, maintained by a take-up unit, ensures proper contact with the drive pulley to prevent slippage. The carrying run of the belt, supported by idlers, transports the material. The empty return run travels back underneath the system on return idlers. Belts can be flat for general cargo or profiled with cleats, sidewalls, or flights to handle loose bulk materials like grain or coal on inclines. The speed of the conveyor belt is adjustable, allowing control over the rate of material flow to match the pace of upstream and downstream processes. This simple yet highly effective mechanism makes the conveyor belt an indispensable tool for automating movement, reducing labor costs, and creating efficient, continuous production and distribution lines across countless industries.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness