Understanding the Standards and Construction of Low Voltage Motors

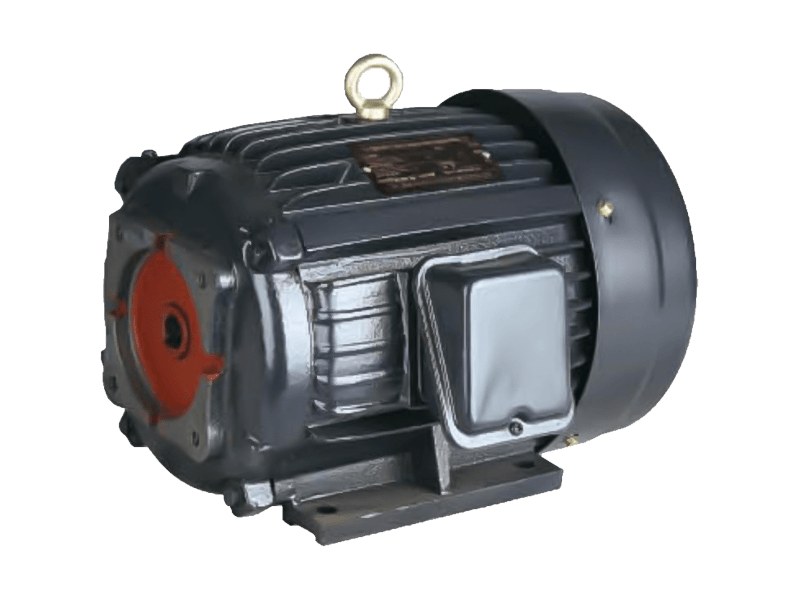

A low voltage motor is an electric motor designed to operate on a power supply with a rated voltage below a specific threshold, commonly understood in industrial contexts as 1000 volts AC or 1500 volts DC. This classification encompasses a vast majority of motors used in commercial, residential, and general industrial applications. The defining characteristic of a low voltage motor is its accessibility and integration into standard electrical distribution systems without requiring specialized high-voltage switchgear or extensive safety clearances. Common voltage ratings for a three-phase low voltage motor include 230V, 400V, 480V, and 690V, aligning with typical facility power supplies. The design and construction of a reliable low voltage motor focus on efficiency, thermal management, and robust insulation systems suitable for these lower potential differences.

The internal architecture of a low voltage motor is engineered for its operating environment. The stator windings are insulated with materials rated for the specific voltage class, such as enamel-coated wires and slot liners. For a low voltage motor, the insulation system must guard against electrical breakdown due to voltage spikes, moisture, and thermal stress. The rotor, whether squirrel-cage or wound, is built to handle the electromagnetic forces generated at these voltages. Cooling is typically achieved through an integrated fan or external ventilation, as the compact size and high power density of many low voltage motor designs necessitate effective heat dissipation. Bearings and mechanical structures are standardized for widespread compatibility with pumps, fans, compressors, and conveyors.

Safety and installation practices for a low voltage motor are less stringent than for medium or high-voltage equipment but remain critical. Proper grounding is essential to prevent shock hazards. Overcurrent protection via circuit breakers or fuses is required to safeguard the windings from damage due to overloads or short circuits. The control of a low voltage motor often involves simple contactor-based starters or more advanced variable frequency drives, which allow for soft starting and speed control. The ubiquity of the low voltage motor stems from its balance of performance, safety, and cost-effectiveness. It serves as the fundamental prime mover in countless systems, from the HVAC unit in a building to the drive system on a factory floor, demonstrating that a low voltage motor is not defined by limitation but by its optimized adaptation to the most common electrical infrastructures worldwide.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness