The Lifecycle and Performance Validation of Viscous Friction Damper Systems

The design and specification of a viscous friction damper require precise engineering analysis to match the device's characteristics to the dynamic demands of the host system. Key parameters must be defined: the damping coefficient, which quantifies the relationship between force and velocity; the maximum damping force capacity; and the maximum stroke or displacement the piston rod must accommodate. Engineers perform dynamic analyses of the structure under expected loads (wind, seismic) to determine the optimal placement, quantity, and properties of the viscous friction damper units. The goal is to achieve a target level of additional damping for the structure, often expressed as a percentage of critical damping.

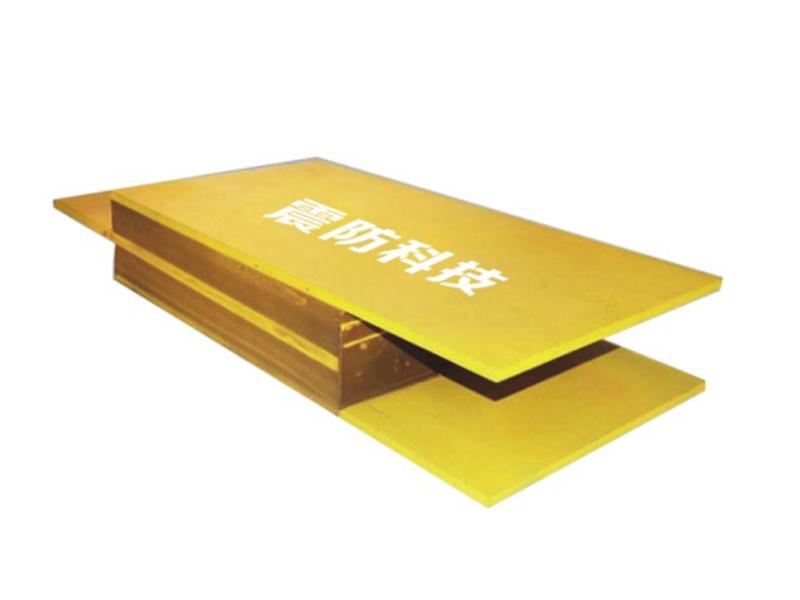

Manufacturing a reliable viscous friction damper involves high-precision machining and rigorous quality control. The cylinder must be perfectly sealed to prevent leakage of the silicone fluid over decades of service. The piston and rod assembly are machined to tight tolerances to ensure consistent fluid flow through the orifices. The specialized damping fluid is carefully degassed and injected under vacuum to eliminate air bubbles that could compromise performance. Before delivery, each viscous friction damper undergoes prototype and production testing. This typically includes dynamic testing on a servo-hydraulic actuator, where the damper is subjected to cyclic loading at various frequencies and amplitudes. The resulting force-velocity-displacement data is analyzed to verify that the viscous friction damper meets its design specifications and exhibits stable hysteretic behavior.

Once installed, a viscous friction damper system requires minimal but important maintenance. Being a passive, sealed unit, it has no moving parts that require lubrication. The primary maintenance activity is periodic visual inspection. Engineers check for any signs of fluid leakage, which would appear as an oily residue around the rod seals or connections. The physical condition of the mounting brackets and pins is also inspected for corrosion or wear. While the design life of a viscous friction damper often matches or exceeds that of the structure, some specifications may call for periodic performance testing in situ, though this is complex. The long-term reliability hinges on the quality of the seals and the chemical stability of the fluid. By following a disciplined approach from design and manufacturing through to installation and routine inspection, a viscous friction damper provides a durable and dependable means of protecting structures from dynamic forces. Its successful implementation represents a fusion of fluid mechanics, materials science, and structural engineering, creating systems that are not just stronger, but smarter in how they manage and dissipate destructive energy.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness