Does Thickness Affect Wire to Board Connector Performance?

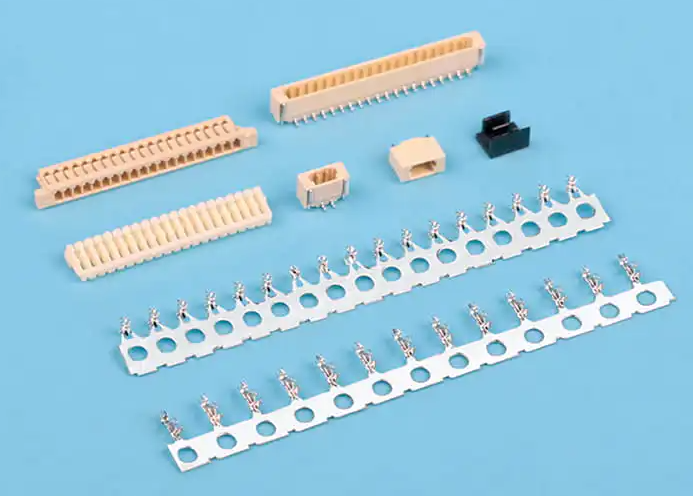

Introduction to WTB Wire to Board Connectors

A WTB Wire to Board Connector is widely used in electronic applications to provide secure and reliable connections between wires and printed circuit boards (PCBs). While many users focus on factors like pin count, current rating, and material, the thickness of the connector is also an important consideration. Connector thickness can affect mechanical stability, electrical performance, and compatibility with specific PCB layouts. Understanding how thickness influences usage is crucial for designers and engineers aiming for optimal performance and long-term reliability.

Mechanical Stability and Durability

The thickness of a WTB connector directly impacts its mechanical strength. Thicker connectors generally provide greater rigidity and resistance to bending or deformation. This is particularly important in applications where the connector may be subjected to vibration, mechanical stress, or repeated insertion and removal cycles. Thinner connectors may offer space-saving advantages, but they can be more prone to warping or breaking under stress. Balancing thickness with mechanical stability ensures that the connector maintains a secure and reliable physical connection throughout its service life.

Electrical Performance Considerations

Connector thickness also affects electrical performance. A thicker connector can accommodate larger contact surfaces, which reduces contact resistance and improves current-carrying capacity. This is essential for high-current applications or environments where consistent signal transmission is critical. Conversely, overly thin connectors may have smaller contact areas, which could lead to increased resistance, localized heating, and potential signal degradation over time. Engineers must consider the required electrical load when selecting a connector thickness to ensure reliable operation.

PCB Compatibility and Layout

WTB connectors must fit accurately within the design constraints of a PCB. Connector thickness affects the vertical spacing between the wire and the board, which in turn influences component placement and soldering processes. A connector that is too thick may interfere with adjacent components or prevent the enclosure from closing properly. Conversely, a thinner connector may allow for tighter layouts and more compact designs but may compromise mechanical and electrical robustness. Selecting the correct thickness ensures both functional performance and compatibility with the overall design.

Thermal Management and Environmental Factors

In addition to mechanical and electrical considerations, thickness can influence thermal management. Thicker connectors often dissipate heat more effectively due to increased material mass, which reduces the risk of overheating in high-power applications. Environmental factors such as temperature fluctuations and exposure to vibration can also affect thinner connectors more severely. Choosing an appropriate thickness helps maintain connector integrity under varying environmental conditions, ensuring consistent performance and longer lifespan.

The thickness of a WTB Wire to Board Connector significantly affects its mechanical stability, electrical performance, PCB compatibility, and thermal management. While thinner connectors may save space in compact designs, they may compromise durability and current-handling capability. Thicker connectors provide enhanced strength and better contact reliability, making them suitable for demanding applications. Evaluating the specific requirements of the application, including mechanical stress, electrical load, and environmental conditions, is essential to selecting the optimal connector thickness. By carefully considering these factors, designers can ensure long-lasting, reliable performance for their wire-to-board connections.

1、CKT: 2*3Pin to 2*25Pin

2、Current rating: 1A AC/DC

3、Voltage rating(max): 50V, AC/DC

4、Working Temperature: -25°C~+85°C,

(Including temperature rise in applying electrical current)

5、Contact resistance: Initial value S20mΩ

After environmental testing≤40mΩ

6、Insulation resistance: 2100MΩ

7、Withstand voltage: 500VAC(rms)

8、Applicable wire: AWG #32 to #28

9、Applicable PCB board thickness: 1.6mm to 2.0mm

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness