How Rubber Adhesive Agent Reacts at Different Temperatures

Importance of Temperature on Adhesive Performance

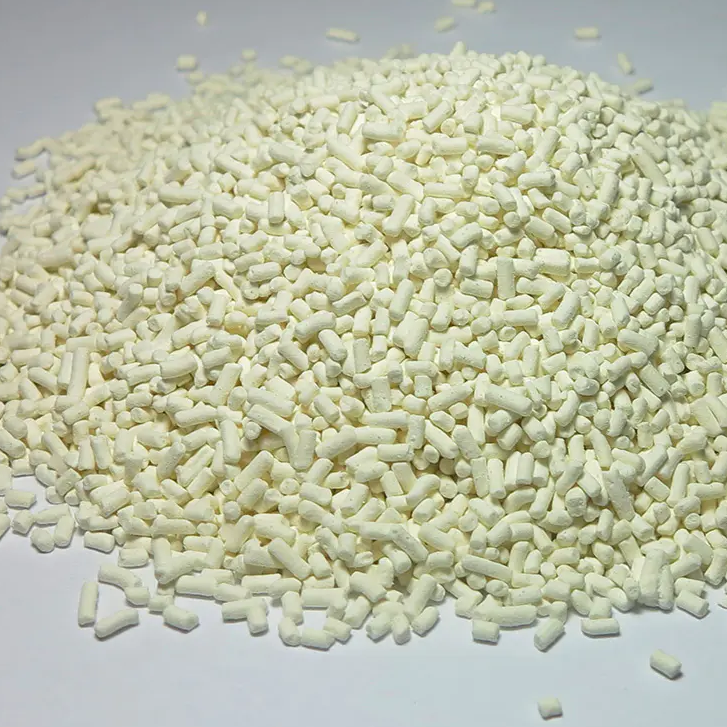

Rubber adhesive agents are critical components in the manufacturing and assembly of rubber products. They facilitate strong bonding between rubber surfaces or between rubber and other materials, such as metals or fabrics. One of the most important factors influencing their effectiveness is temperature. The activity and stability of rubber adhesive agents can vary significantly under different temperature conditions, affecting bond strength, curing time, and long-term durability. Understanding how temperature impacts these adhesives allows manufacturers to optimize processing and ensure consistent product quality.

High-Temperature Effects on Adhesive Activity

At elevated temperatures, rubber adhesive agents generally exhibit increased reactivity. Heat accelerates the chemical reactions that enable bonding, often reducing the time required for curing. While this can improve production efficiency, excessive temperatures can lead to over-curing or degradation of the adhesive. Overheated adhesive may lose its flexibility, become brittle, or produce unwanted byproducts that weaken the bond. Therefore, selecting an adhesive with a high thermal tolerance and monitoring temperature closely during processing is essential for maintaining consistent performance.

Low-Temperature Effects on Adhesive Activity

Conversely, low temperatures tend to slow down the chemical reactions of rubber adhesive agents. Reduced activity can result in longer curing times, incomplete bonding, and weaker adhesion. In extreme cold conditions, some adhesives may fail to initiate curing entirely, causing defects or delamination in the final product. To mitigate these risks, manufacturers often preheat the surfaces or adjust formulation components to maintain adhesive activity at lower temperatures. Choosing an adhesive with a wide operating temperature range ensures that the product can perform reliably in diverse environmental conditions.

Stability Across Temperature Ranges

The stability of rubber adhesive agents under fluctuating temperatures is critical for both storage and application. High-quality adhesives are formulated to resist thermal degradation, oxidation, and viscosity changes over time. Consistent chemical composition ensures that the adhesive retains its bonding capability, even after repeated exposure to hot or cold conditions. Proper storage in controlled environments, away from extreme heat or freezing, further preserves adhesive stability and prolongs shelf life. Adhesives sourced from a reputable Rubber Adhesive Agent supplier often undergo rigorous testing to guarantee thermal stability.

Practical Considerations in Manufacturing

To achieve optimal bonding, manufacturers must consider temperature as a key parameter in the production process. Surface preparation, curing temperature, and exposure duration must all be controlled to align with the adhesive’s activity profile. Adjustments in adhesive formulation may also be necessary for specialized applications, such as bonding in high-temperature engines or cold-weather environments. Following manufacturer guidelines ensures that the adhesive performs consistently, regardless of the operating conditions.

Ensuring Reliable Adhesive Performance

The activity and stability of rubber adhesive agents are highly dependent on temperature. High temperatures can accelerate bonding but risk over-curing, while low temperatures may slow reactions and reduce bond strength. Selecting adhesives with suitable thermal properties, maintaining proper storage conditions, and carefully controlling manufacturing parameters ensures reliable performance. By understanding temperature effects, manufacturers can produce durable, high-quality rubber products that meet stringent performance requirements.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness