Applications of Modified Bumper Molding

Modified bumper molding is a customizable and essential element in modern vehicle design, offering both functional protection and aesthetic enhancement. This type of molding can be tailored to meet specific design needs, providing an effective solution for vehicle manufacturers and owners looking for durability and a personalized look.

Enhanced Protection and Impact Absorption

One of the primary applications of modified bumper molding is to protect the bumper and vehicle frame from minor impacts and collisions. The molded materials, which are often more durable and flexible than standard bumper components, help absorb the force of low-speed impacts, reducing the risk of damage. For vehicle owners concerned about the potential for scratches, dents, or dings from parking lot accidents or minor collisions, modified bumper molding serves as a cost-effective solution for preventing expensive repairs.

Aesthetic Customization and Styling

In addition to its protective qualities, modified bumper molding is widely used for aesthetic purposes. By altering the shape, color, and finish of the molding, manufacturers and car enthusiasts can customize the appearance of their vehicle. Whether aiming for a sleek, modern look or a sporty, aggressive appearance, modified bumper molding offers the flexibility to enhance a vehicle's overall design. This feature is particularly valuable for those looking to personalize their car or for car manufacturers that want to create a distinct brand identity through styling.

Versatility in Automotive Applications

Modified bumper molding is used across a wide range of automotive applications, from luxury vehicles to performance cars and off-road trucks. It can be adapted to suit different vehicle types, offering a balance between form and function. Additionally, modified molding can be engineered to include special features, such as built-in aerodynamics for better airflow, integrated sensors, or LED lighting for increased visibility, making it an ideal choice for both practical and cutting-edge designs.

https://www.bumpermould.net/product/bumper-mould/2020-for-skoda-kamiq-plastic-injection-front-bumper-mould.html

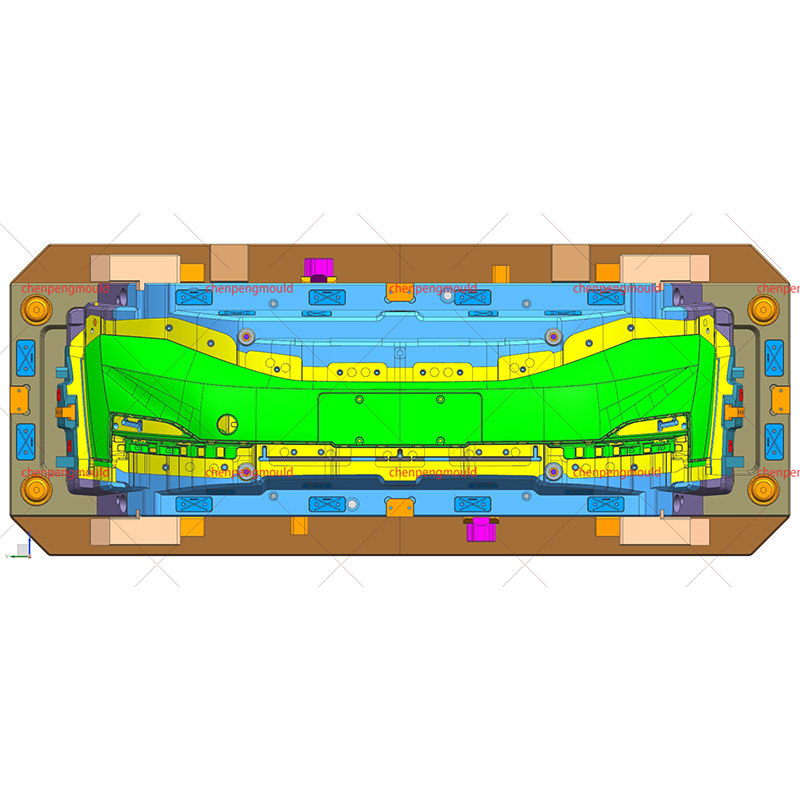

Mould Name Skoda Kamiq Bumper Mould

Material PP+EPDM(Contraction: 1, 5%)

Bumper Size 1800*510*460mm

Steel For Cavity &. Core P20

Mould Base C45

NOs. of Cavity 1*1

Injection System Yudo 5 direct injection gates

Ejection System Ejector pins, angle lifters

Mould Standard OEM/HASCO

Mould Estimated Size 2200 x 950 x 1000mm

Mould Weight 12500KG

Injection Machine Size 1850T

Mould Lifetime 5years

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness