VKJP84887 Roller Ball Bearing for Heavy Duty

Industrial equipment depends on stable rotational motion. When bearings fail, machines stop. This article explains how VKJP84887 improves load performance, reduces downtime, and supports demanding B2B applications.

The Industry Problem: Bearing Failure and Downtime

In industrial systems, bearings operate under constant stress. Heavy loads, high speeds, and harsh environments can quickly damage low-quality components.

Common issues include:

-

Excessive vibration

-

Overheating

-

Shaft misalignment

-

Premature wear

-

Unexpected shutdowns

For OEM manufacturers and industrial operators, bearing failure increases maintenance costs and impacts production schedules. Even a single weak component can affect the entire system.

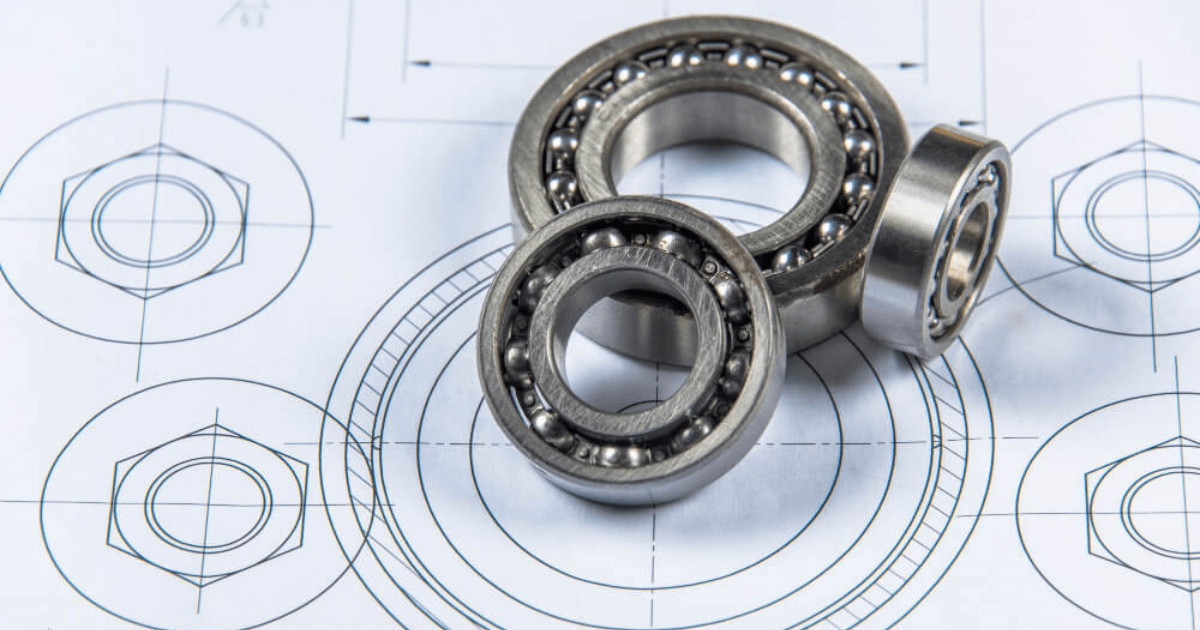

What Is VKJP84887 and How Does It Work?

VKJP84887 is a mechanical roller ball bearing designed to support rotational movement while reducing friction. It distributes load evenly between rolling elements and raceways, ensuring smooth motion and mechanical stability.

The internal rolling structure:

-

Minimizes metal-to-metal contact

-

Reduces friction loss

-

Controls heat buildup

-

Improves energy efficiency

For detailed product specifications and industrial compatibility, manufacturers can review vkjp84887 as a reliable solution for heavy-duty mechanical systems.

Limitations of Traditional Bearings

Standard or low-grade bearings often struggle with:

-

Uneven load distribution

-

Weak material hardness

-

Limited fatigue resistance

-

Poor lubrication performance

-

Corrosion under moisture exposure

In high-load environments, these limitations shorten service life and increase replacement frequency. For B2B buyers, repeated failure leads to higher lifecycle costs and operational instability.

How VKJP84887 Solves These Challenges

Enhanced Load Capacity

The roller-ball configuration improves contact distribution and supports higher mechanical stress.

Durable Hardened Steel Construction

Precision heat treatment increases wear resistance and structural integrity.

Reduced Friction and Heat

Engineered internal geometry maintains stable performance even during continuous operation.

Long Service Life

Optimized surface finishing reduces fatigue and extends operational cycles.

Industrial buyers seeking consistent performance can evaluate vkjp84887 for demanding automotive and mechanical applications.

Key Features Engineers Should Consider

When selecting roller ball bearings, evaluate:

-

Radial and axial load capacity

-

Dimensional accuracy

-

Surface hardness ratings

-

Tolerance precision

-

Lubrication compatibility

-

Corrosion resistance

-

Quality certification standards

For manufacturers, supplier reliability and consistent production batches are equally important.

VKJP84887 vs Generic Bearings

| Feature | VKJP84887 Roller Ball Bearing | Generic Bearing |

|---|---|---|

| Load Performance | High-load optimized | Moderate |

| Material Strength | Heat-treated steel | Variable |

| Friction Control | Precision engineered | Basic |

| Durability | Extended service life | Shorter lifespan |

| Industrial Suitability | Heavy-duty systems | Light to medium use |

For OEM production and industrial machinery, the performance difference directly affects maintenance frequency and total cost of ownership.

Real Industrial Applications

VKJP84887 is commonly used in:

-

Automotive transmission assemblies

-

Industrial motor systems

-

Gearbox mechanisms

-

Construction equipment

-

Agricultural machinery

-

Mechanical drive units

In these applications, stable rotation improves energy efficiency and reduces operational vibration.

Why Manufacturers Prefer High-Performance Bearings

Manufacturers choose performance-grade bearings because they:

-

Reduce machine downtime

-

Improve final product reliability

-

Lower warranty claims

-

Increase operational safety

-

Meet international quality standards

In export markets, consistent bearing quality strengthens brand reputation and long-term customer trust.

How to Choose the Right Bearing for Your Application

Before selecting VKJP84887, engineers should review:

-

Required load ratings

-

Operating speed conditions

-

Temperature exposure

-

Environmental contamination risk

-

Mounting alignment accuracy

-

Lubrication system compatibility

-

Supplier technical support and certifications

Matching the bearing specification to system requirements ensures long-term reliability and cost efficiency.

Conclusion

Bearing performance directly impacts industrial productivity. Low-quality components increase downtime, repair costs, and system risk.

VKJP84887 provides durable construction, smooth rotational efficiency, and strong load capacity for demanding mechanical systems. For B2B buyers, engineers, and manufacturers, selecting a precision-engineered roller ball bearing is a strategic investment in long-term operational stability.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness