The Technology and Benefits Behind WPC Door Manufacturing

A modern WPC door factory is defined by its technological infrastructure and the resulting product advantages it can deliver to the market. The choice to manufacture with Wood Plastic Composite is a strategic one, and the factory's design reflects a commitment to leveraging this material's strengths. The equipment within such a facility, from advanced compounding extruders to precision CNC centers, is selected to process the composite efficiently and accurately. This technological foundation enables the factory to produce doors that address specific shortcomings of traditional materials, such as wood's susceptibility to water and pure plastic's lack of structural feel. The capabilities of the WPC door factory thus directly translate into the performance characteristics and design versatility of the WPC doors it produces.

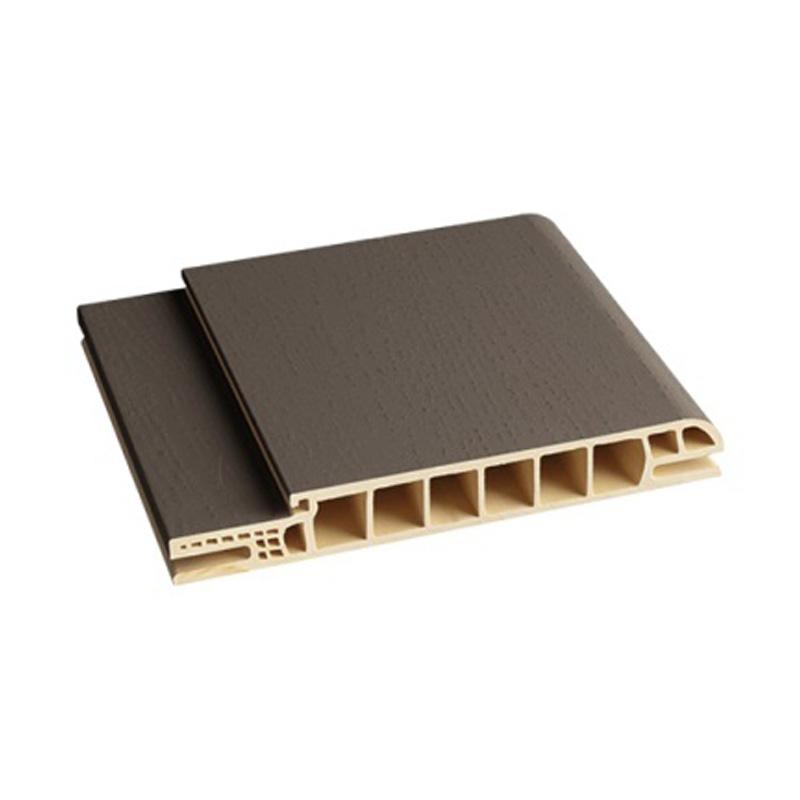

The technological edge of a proficient WPC door factory begins with material formulation and extrusion control. The ability to fine-tune the ratio of wood flour to polymer, and to incorporate additives for UV stability, color fastness, and fungal resistance, is a core competency. State-of-the-art extrusion lines with precise temperature and screw speed controls ensure the WPC profile emerges with consistent density and a smooth surface, which is crucial for subsequent finishing. Post-extrusion, the factory relies on computerized machining. CNC routers and saws handle the WPC material with programs designed to minimize chipping and achieve clean edges, allowing for intricate designs like French door lites or detailed paneling that would be challenging with inconsistent natural wood.

The product advantages stemming from a WPC door factory are significant. First is dimensional stability. WPC is much less prone to warping, swelling, or shrinking with changes in humidity compared to solid wood, a key benefit for consistent door operation. Second is moisture and decay resistance. The plastic matrix in WPC protects the wood fibers, making doors suitable for bathrooms, laundry rooms, and other high-humidity interiors where wood might fail. Third is low maintenance. WPC doors do not require regular sanding, staining, or varnishing; their color is integral or protected by a durable foil, needing only occasional cleaning. These performance traits are engineered into the product through the controlled processes of the factory, offering durable and practical solutions for residential and light commercial projects.

The product range from a WPC door factory can be extensive, demonstrating its flexibility. A standard offering includes interior slab doors in various thicknesses and sizes, often with options for different surface finishes like wood-grain foils in oak, walnut, or ash patterns. More advanced factories produce doors with molded designs, decorative raised panels, or even full-length glass inserts for patio applications. The ability to create consistent, paintable surfaces also allows for custom color matching. Some facilities specialize in complete door systems, including matching WPC door frames and jambs, providing a full-package solution for builders. The factory's capacity to offer both standardized catalog items and tailored solutions is a testament to the adaptability of WPC as a manufacturing material and the sophisticated systems in place to work with it.

A WPC door factory is more than a production site; it is an engineering hub that transforms a defined material recipe into a high-value building product. Its technology is geared toward consistency and exploiting the composite's inherent benefits. The doors that come off its line are marketed not on traditional craftsmanship but on engineered performance: stability, moisture resistance, and ease of upkeep. As the construction industry continues to seek materials that offer longevity with minimal environmental impact from maintenance, the role of the technologically adept WPC door factory becomes increasingly relevant, providing a modern, composite-based answer to the timeless need for functional and attractive doors.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness